SCH404: Weirdness Not Found

“What the hell is this?” I hear you ask. “This looks like the ordinariest ordinary thing that ever ordinaried.”

Here’s a hint, by way of a magnet.

The Schrade SCH404 is indeed one of those from the burgeoning, but still uncommon, sector of ceramic bladed knives. But unlike the cheapie translucent ones that Amazon perpetually refuses to ship to your location, this one has a zirconia ceramic blade with this attractive obsidian finish.

The SCH404 is very old and thus very discontinued. So much so that it’s actually pretty tough to find any info on it online. It’s also one of those things that perfectly illustrate how us spacemen are already living in the future, but we’re so numb to everything nowadays that the mere presence the advanced wondermaterials it’s made out of – things unfathomable to an observer from, say, fifty years ago – now just feel like they’re old hat.

And this was an inexpensive entry level knife in its day, not even remotely premium.

But despite its age, the SCH404 still has quite a few modern aspects about it. Like like the deep carry pocket clip, highly textured G10 scales, and slick single sided liner design. These are all highly desirable hallmarks of current EDC knives. Just in this case also including a blade made of a weird nonmetallic material.

For a start, this is a very light and compact knife. It’s only 48.7 grams or 1.72 ounces – that’s actually 2.4 grams lighter than a Benchmade Bugout. It’s just 3-3/4" long closed, 6-1/2" open, and sports a 2-3/4" long blade made of that groovy glassine ceramic. I think the only way to go lighter per displacement would be to pay a lot more and pony up for the likes of, say, a Böker Anti Grav.

The SCH404 is pretty thin overall as well. It’s 0.346" thick not including the clip, with its lack of bulk in both dimensions and weight combining to make it very easy to carry. The ceramic blade is 0.80" thick.

Actually, let’s talk about that blade.

Ceramic blades like this one are typically billed as “forever sharp.” The zirconia ceramic material is incredibly hard, falling somewhere between 8.5 and 9 on the Moh’s scale and thus much harder than steel. It resists abrasion to an incredible degree, and is essentially completely immune to the inherent abrasiveness of cardboard, sisal rope, leather, and even wood.

The glossy obsidian surface is a veritable beacon for fingerprints but not, it must be said, scratches. There is very little that can truly scratch the surface of the SCH404’s blade. Basically only sapphire, diamond, and tungsten carbides – all things you’re unlikely to be trying to slice with your pocketknife on a daily basis.

But the material is also very brittle, and the thinner it is the more brittle it gets. Thus a ceramic knife like this chips near-microscopically rather than dulling via abrasion or the edge getting rounded down like a typical steel knife. It’s also not a good idea to put any torsion on it at all, because the material would be prone to just snap.

And I know what you’re thinking. No, this knife will not sail through a metal detector. The liner, clip, and screws are all made of plain old steel. So forget it. Only the blade and scales are nonmetallic.

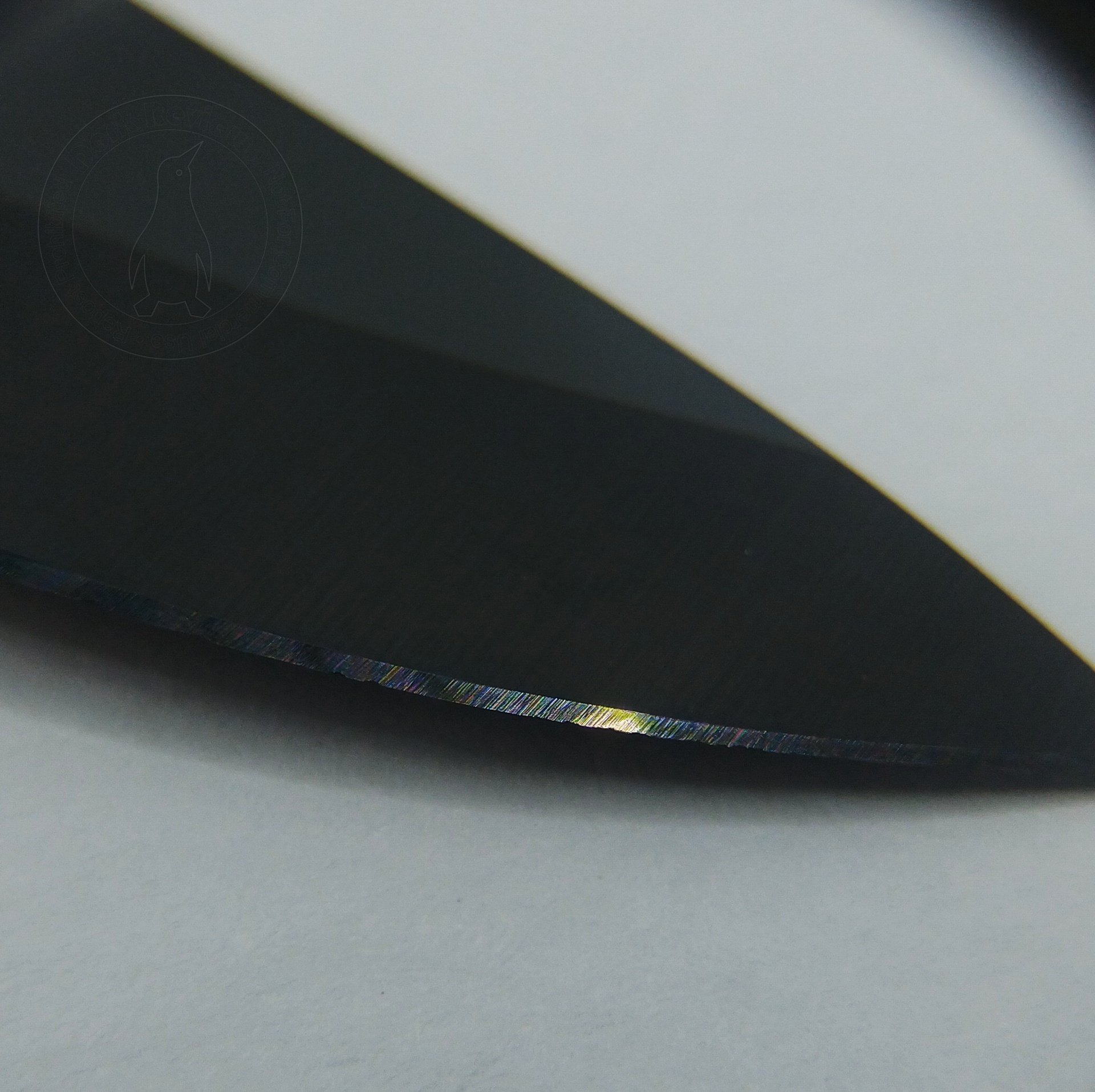

It’s a very good thing these come preground, because they are functionally impossible for a hobbyist to properly sharpen. Yes, you can theoretically do the job with resin bonded diamond stones but the process is arduous and difficult, and the penalty for failure is high. My example is very lightly used, so I can only imagine these tiny imperfections in the edge came from the factory. The SCH404 is not quite shaving sharp although it glides through paper and cardboard quite easily still. That’s just as well, because if it were truly dull I probably wouldn’t be too keen to do anything about it.

I dig the subtle refractive rainbow effect of the light playing off of the texture in the edge like a starling’s wing. The SCH404’s blade really is stunningly beautiful. The flat of the blade is literally mirror polished, to the point that it casts reflections. The machine marks, meanwhile, sparkle in the light. It’s like waving a black diamond around.

The edge is also fortunately exactly mathematically true. As it bloody well ought to be, given all of the above. If it weren’t, good luck trying to correct it.

So, I mentioned the Böker Anti Grav earlier, and I did that on purpose. That’s because I suspect, but cannot prove, that this knife was actually OEM’ed by Böker using much of the same equipment, material, and template.

What clues me in is this highly distinctive five-holed spanner nut on the pivot, which is suspiciously reminiscent of the one on the Anti Grav and its sibling, the Anti MC. If so, that’s huge – that makes this an incredible poor man’s version of that knife, especially considering that the former retails for about $195 nowadays. The main thing you’re lacking is the zooty carbon fiber or titanium scales, but for the end-of-life retail cost of around $15 on this thing I’ll sure take the $180 discount. So if that’s true, there’s the other half of the oddity surrounding this knife. We’ll probably never know for sure.

I bothered to take a macro photo of the SCH404’s model number etching, so I’m going to show it to you and nobody’s going to stop me. Here it is.

Size wise, the SCH404 falls firmly into the compact category. It’s basically the size of a Mini Bugout. Compared to the usual CQC-6K, there, it’ll ride thoroughly unnoticed in your pocket.

The Inevitable Conclusion

You can’t buy the SCH404 anymore, so there wasn’t much point in me yammering on about it. But it’s the only folding ceramic knife I own these days so it’s the one you got.

Ceramic knives like these – in their pocket knife incarnations, anyway, and not as the fairly ubiquitous cheap white kitchen knives – shine for basically one and only one purpose. If your workflow involves cutting a lot of cardboard in a day, something like this absolutely will save you from endless resharpenings or having to go through box cutter blades like popcorn.

Like many things in my collection, both those I’ve shown you and ones I haven’t gotten around to yet, the SCH404 is a bit of a relic. It’s a peculiar combination of materials, construction, and price point we’re not liable to see the likes of again. At least, not for what it cost when it was available.

Ceramic knives excel at cutting tasks but do not handle prying, twisting, or impact very well. They are also 100% corrosion resistant, especially those that don’t have any steel parts in their construction (i.e. not this one, but most of the fixed bladed ones). Cutting cardboard and breaking up boxes, rope and cordage, gutting fish, dressing and skinning, and food prep all leap to mind.

If you want to try it out without a large investment, you can get ceramic box cutter blades cheaply online. These are way thinner than the blade on this knife so arguably even more fragile, but they have the same kind of sharpness and edge retention. That should tell you pretty quickly if your workflow would benefit from an edge that functionally never needs sharpening and can withstand the types of duty cycle you’ll put it through vis-a-vis torsion and prying.