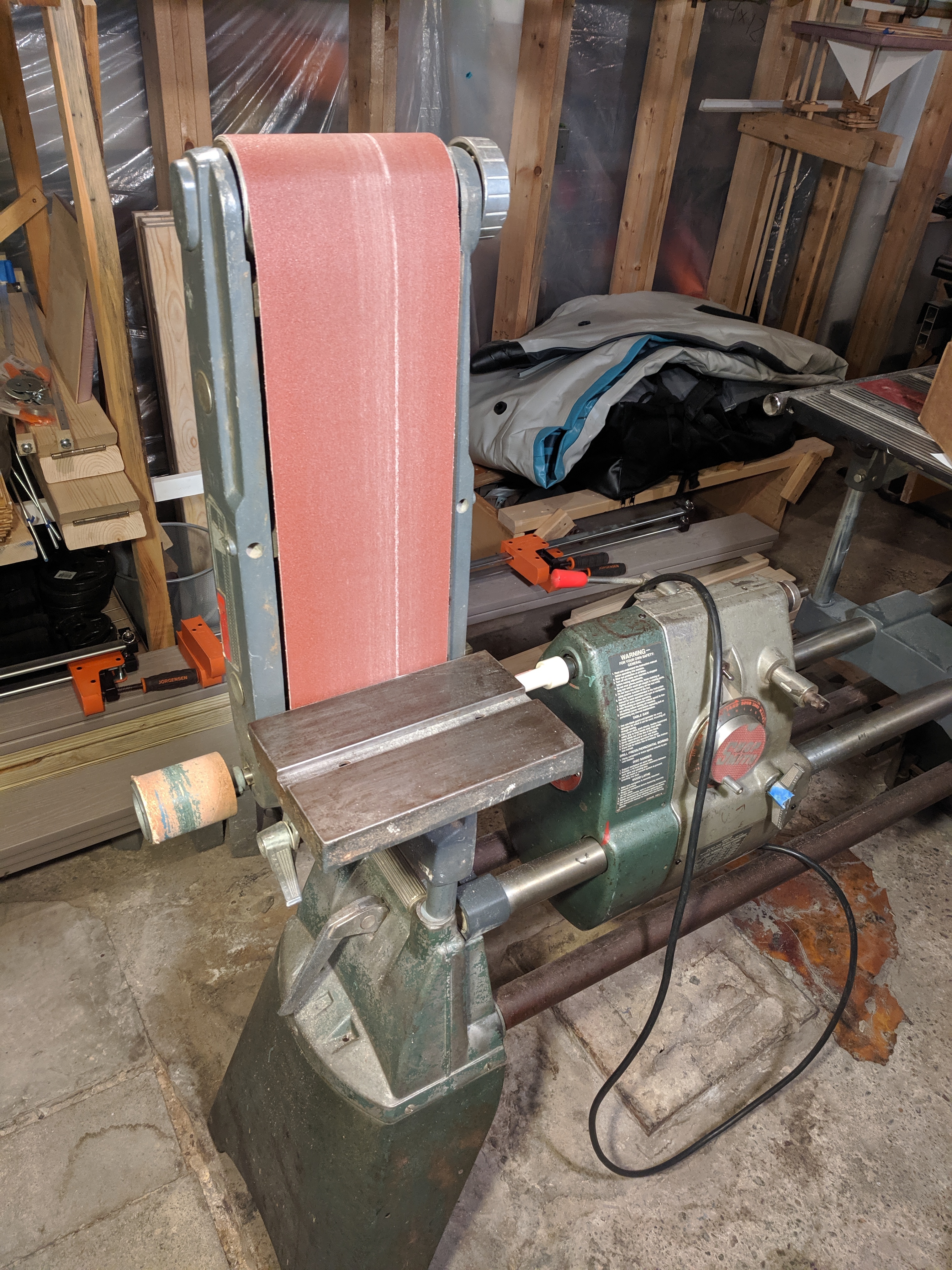

I wasn’t expecting to be able to fit many tools in my basement shop area, so it was a pleasant surprise to learn about the Shopsmith. Pictured are belt sander, jigsaw, and drill press; I’ve also got the band saw, table saw, and lathe.

Wow, looks like somebody updated their greenie to a 510. Good chance it was well-maintained, then. I use my 90s vintage 510 as my lathe, bandsaw, and especially drill press. A used Shopsmith is the best value drill press out there, IMO.

I do not use it for my table saw. Fuck that (though it can be done, and even done fairly safely).

Yeah, they included the original table as well, not sure if I have a use for it. Everything seems pretty well maintained and aligned.

The table saw is a definite upgrade from the deathtrap $50 yard sale one I had before, but I may still go Sawstop one of these days.

So it makes certain things interesting, and I absolutely had to make my own power coupler, but I put the old carriage and table from my 500 that died to the left of the headstock. I use some of the old one’s other leftover parts as outfeed for my motor-hanger Sawstop.

As for the table saw, I hear you. The table even on a 510 is small, but much more usable than a 500, and while tilting the table is always going to be bonkers for TS operations, the overall build quality is so much better than your average plastic jobsite saw that I’d use it if I didn’t have at least one of the mid-range Ridgids or something. Even the DeWalts, with their very nice fences, can be ridiculously tiny if you don’t spring for one of their nicer ones.

You probably already know this, but for the 510 fence (and most “2-point” fences), a little forward pressure while locking down avoids much of the slop that Biesemeyer stans complain about when using anything else.