Glad for advice on getting mitered corners more precise, I ended up with little gaps using both a table saw crosscut sled and miter saw. I think part of the issue is holding the small pieces of wood totally still.

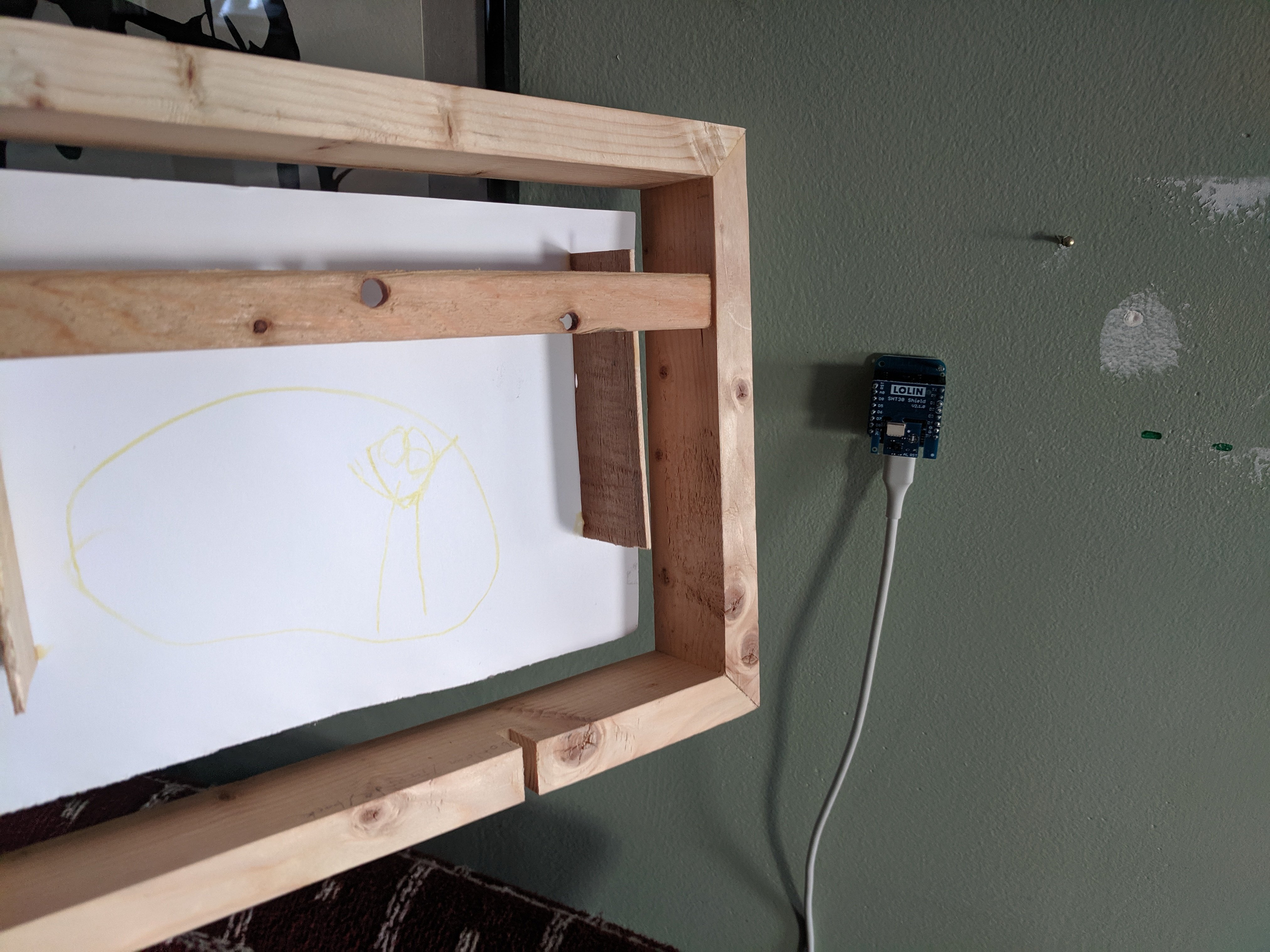

Don’t forget to make sure that the temperature sensor gets proper ventilation or you will start getting odd behavior from your HVAC.

Definitely! I think you can see a little more clearly from the back that there are air gaps all around, but I’ve had problems with temperature sensors self heating on PCBs before so I’ll be on the lookout for that kind of thing.

Ahh, very nice solution!

A lot of times I’ll get gaps when cutting a side too short. Now I’ll try sneak up on the line with a few cuts and dry fit it in between.

A stop block on a miter saw or miter gauge can help get repeated cut lengths better than a pencil line.

The hand tool alternative is a plane and shooting board. Might need a dedicated 45 deg jig or donkey’s ear depending on the size of your pieces.

Somewhat unrelated, but you can get a cable protector to conceal the power cord a bit.

I hadn’t heard of a donkey’s ear shooting board, that looks like a good jig to build. Need to cut an exact 45⁰ first though!

I’ll keep an eye on length too, thanks for the tip.

It might be the camera angle, but those faces might be throwing off the miters. If you’re aiming for perfect miters, starting with planed reference surfaces is a must. The alternative is what was mentioned above: cut proud and sneak up on it.

I think what you’re seeing is that I’m still getting the hand of trimming the splines flush with a chisel and left some unevenness of the surface. But good to double check.