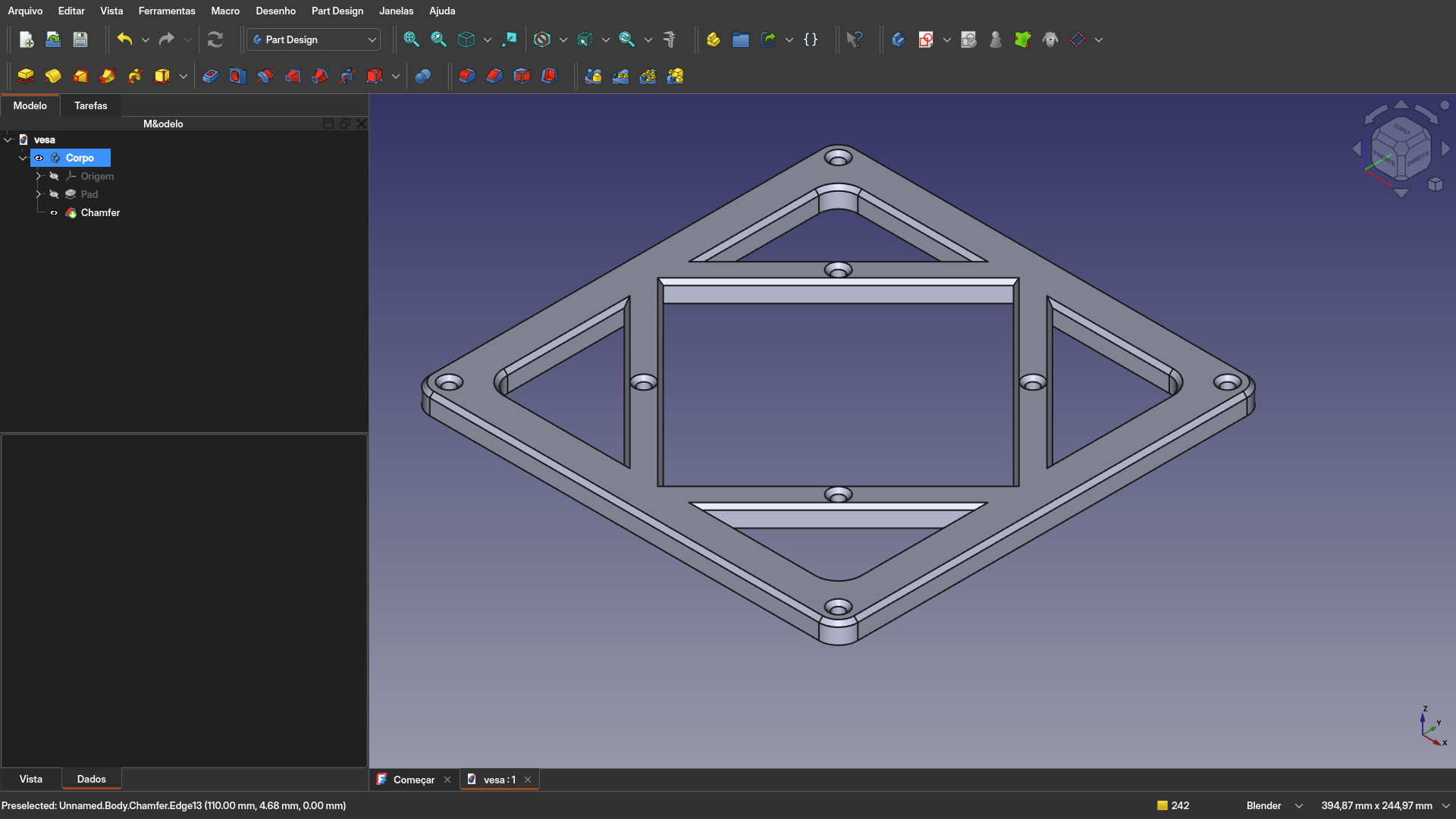

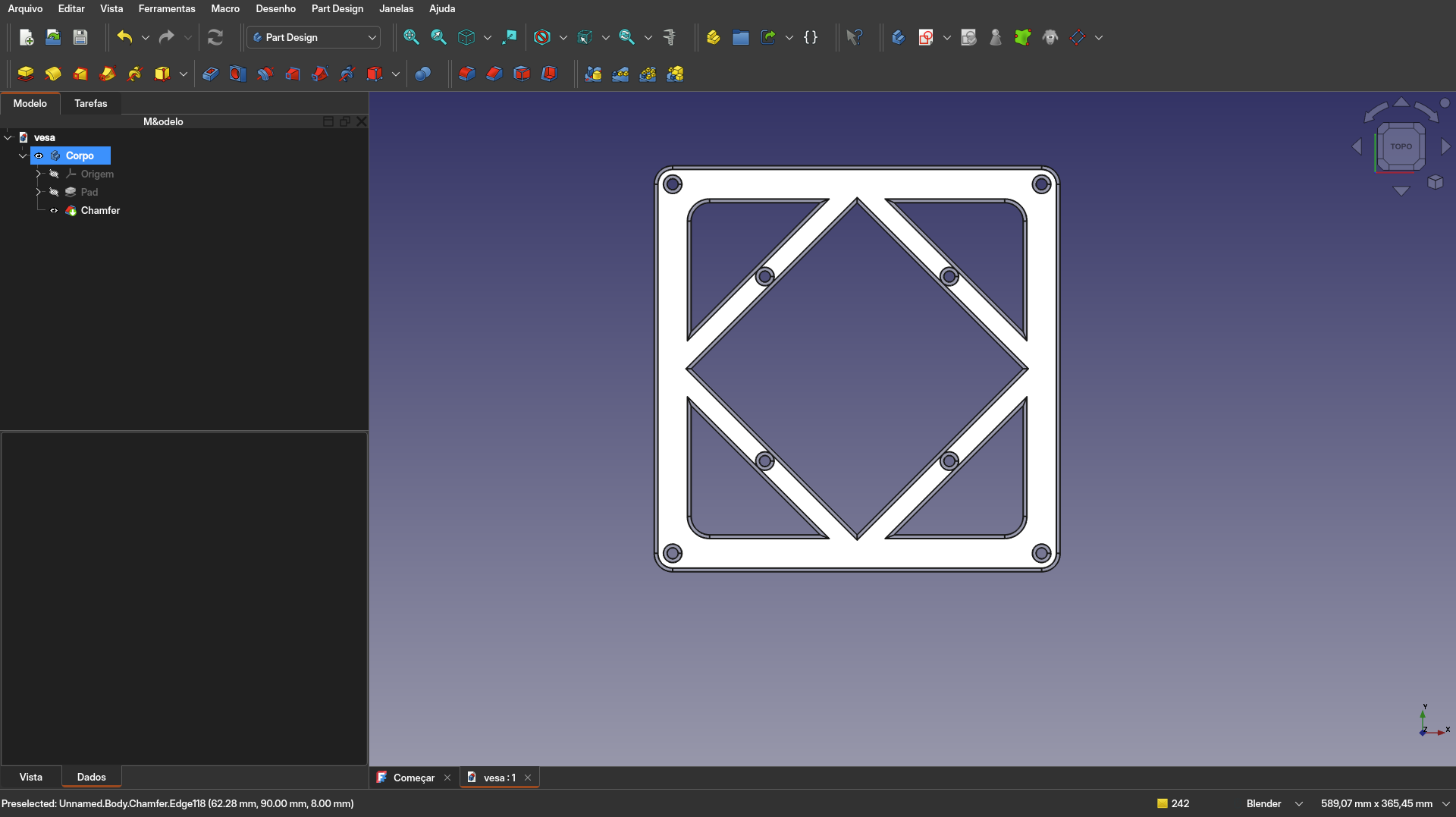

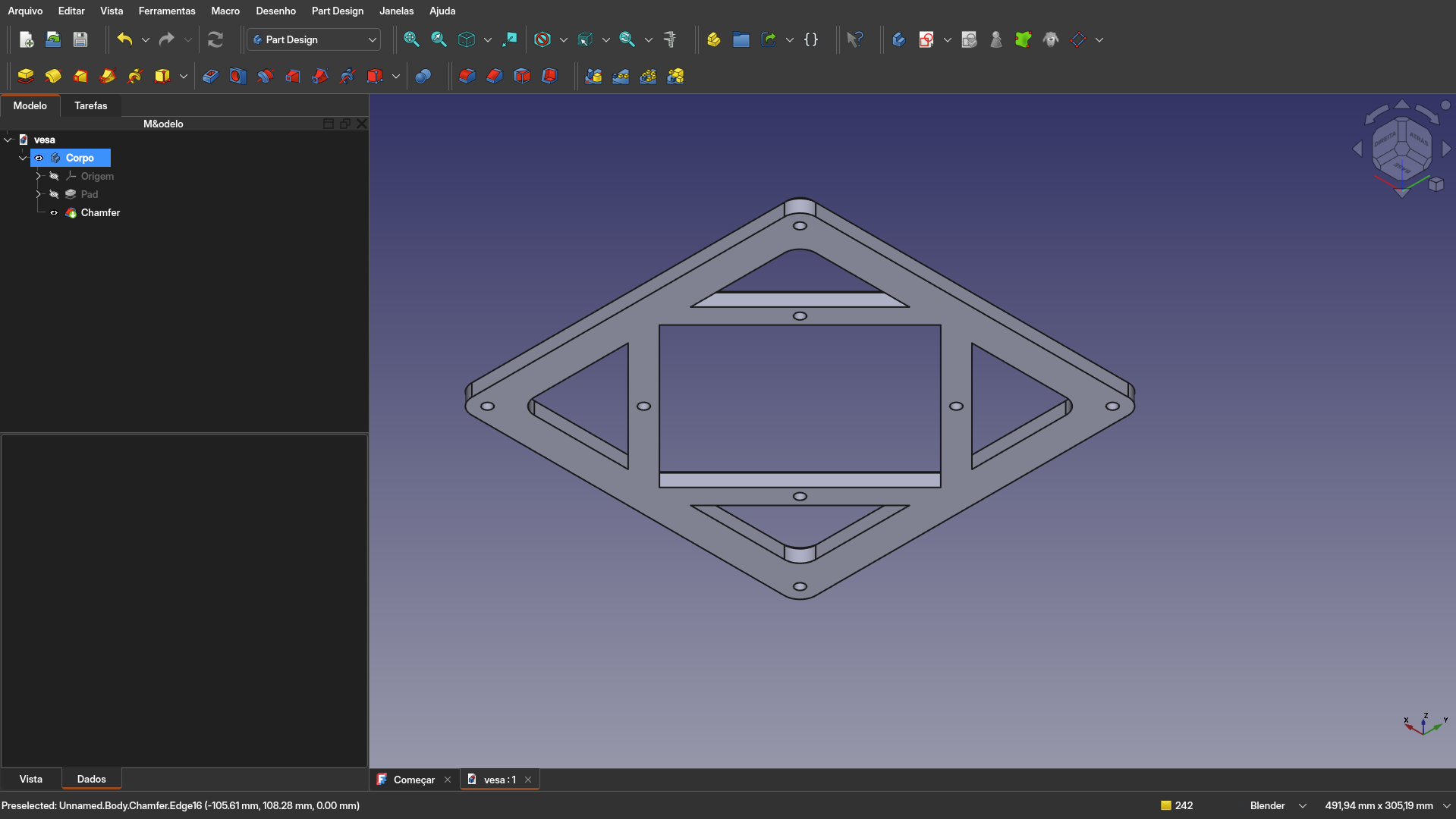

after bashing my head in my table for a bit, i finally managed to make something “salvagable”… i think.

this is meant to be a vesa adapter, from 200mm to 100mm; the idea is that 6mm metal screw-posts are melted into the holes

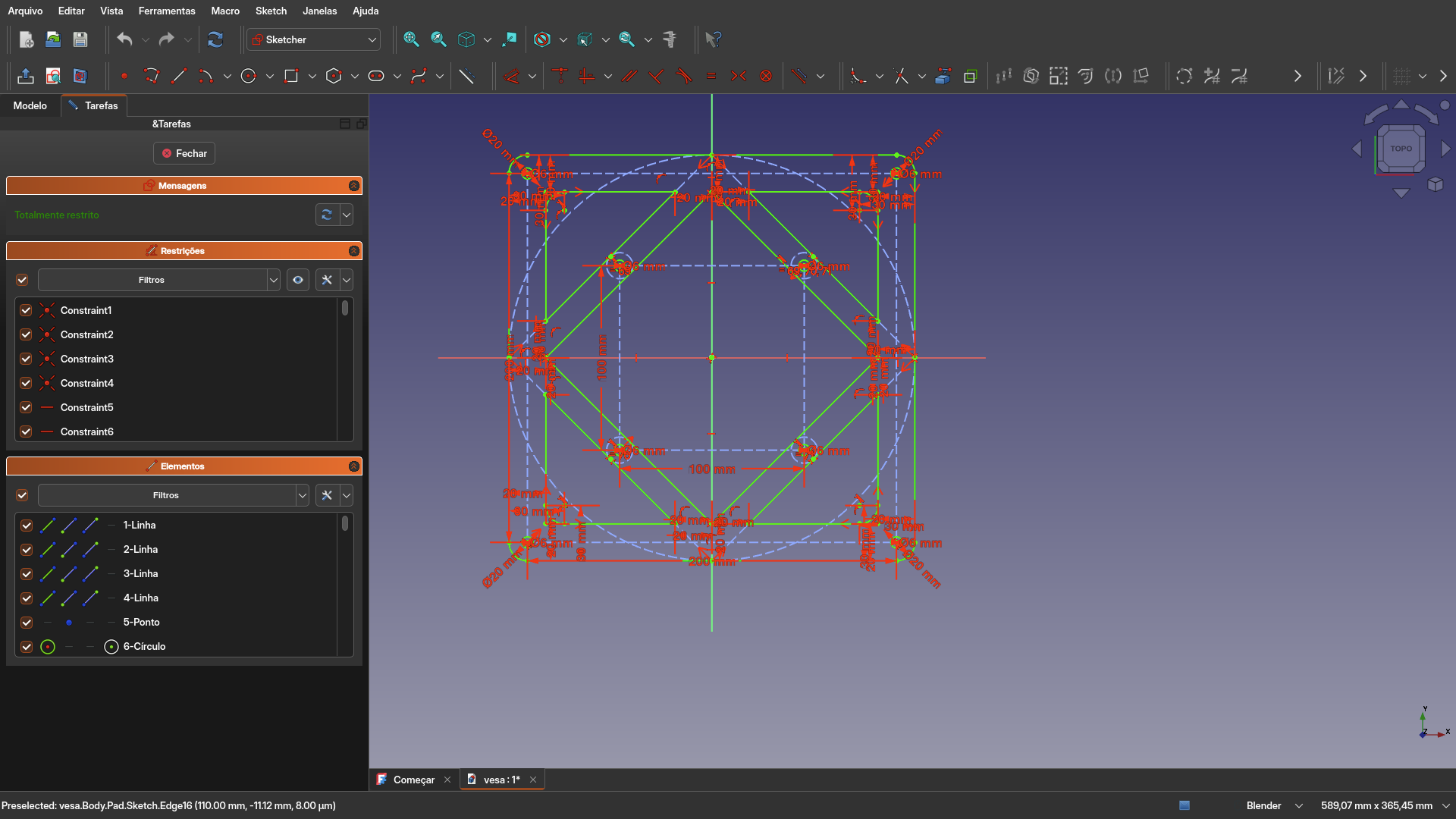

the sketch is quite a bit of a hellscape… i will see if i can figure out symmetry on the next iteration. Do you have any advice on how i can use better this program? it’s been quite a bit since i haven’t seen such a steep learning curve on a piece of software

In cases where you can know ahead of time your part is going to have a lot of repeated dimensions, i.e. it is symmetrical in one or more axes, or you know all the screw holes are going to be X diameter, or whatever, abuse the hell out of the equality constraint. That’s what I do.

Select a bunch of lines and hit E. Now all those lines will always be the same length. Constrain just one of them to whatever length you need; all of them automatically follow suit.

Select a bunch of circles and hit E. Now all those holes will always be the same diameter. Constrain one, you get the idea.

This makes the task of, “Oh crap, I changed one tiny parameter and now I need to find it and change it again 3/7/15/etc. more times” evaporate instantly.