Everything you buy on Wish is a rip off.

Almost everything you buy on Wish is a rip off.

I was reminded to write about these because the other day BudK, after a rather long hiatus, once again mailed me one of their stupid catalogs. I haven’t given BudK any business for many many years. Being infamous purveyors of crap knives has nothing to do with it, because as we all know I am a veritable connoisseur of crap knives. No, and while I proudly identify as a redneck most times, it’s their particular fixation on venerating the confederacy and confederate stuff that brings my piss to a boil. I can buy shitty knives anywhere these days, so I don’t have to buy them from fuckheads.

Anyway, before I chucked the damn thing in the trash I noticed they’re now selling the exact same little switchblades as these – but they’re hawking them for about double what I paid for these on Wish. So if you’ve been eyeballing one of those for whatever reason, here you go.

I do like a good switchblade. And these… well, aren’t that. But they’re actually not that bad. Fully functional, definitely usable…

…And they’re just so little and precious. (Pictured here compared to my usual Kershaw/Emerson CQC-6K for scale. Warning: Not a banana, do not attempt to peel and consume.) They’re the perfect size for you and your half-scale gang of greasers.

This’ll be a twofer, because while the designs of these are a little different they are definitely two chips off the same block. I ordered them at the same time a few years ago and I think they arrived from the same seller. Probably from the same factory, but who knows. The green one, the double edged version with the switch on the face. The silver one, single edged with the switch on the side.

Specs on both of them are pretty much identical: 3-1/4" long overall with about a 2" blade. 30.7 grams (1.08 ounces) each. They’re also only about 1/4" thick, not including the toggle on the green one. The bodies are anodized aluminum, machined pretty crudely on the inside. The blades are allegedly made of “440C” but as you’ll soon see, mine have developed some small rust spots despite never having existed in any environment harsher than around my desk.

If you are, say, Death The Kid both of these will annoy you mightily because they dispense their blades in an off-center fashion. They’re asymmetrical because all the mechanical gubbins are all on one side, as we’ll see soon.

Quality? Well, the edge geometry is a little whack and the blades can be wiggled a fair bit when they’re deployed. But that’s par for the course with OTF switchblades; they kind of just do that. I find the action on mine to be pretty reliable, and since I use these things as desk fidget toys I’ve probably snicked them in and out (especially the green one) several thousand times by now. Neither one has failed me yet, although I haven’t asked anything out of any of them more demanding than slicing an envelope.

Due to the nature of the design there’s not a whole heck of a lot holding the heel of the blade when it’s in the extended position, so it wouldn’t be too tough to break one of these if you used it as a prying tool or a screwdriver. So don’t do that. These are novelties, not collector’s items or workhorses.

Everyone always asks this, and no: You can’t do much of a mischief to anyone by holding the knife up against them and flicking the switch. Even a quality full sized OTF switchblade doesn’t power the blade for anything like its entire travel, and these little things are positively wimpy. You can just about puncture a sheet of paper if you fire the blade at it from an inch away, but even that slows it down so much that it won’t lock open afterwards. (You can just gently pull it to its full extension to lock it if that happens, and then it’ll close normally. There’s no need to yank it sharply, which I see people doing all the time and then cutting themselves. So don’t do that.)

You ever wonder how a switchblade works?

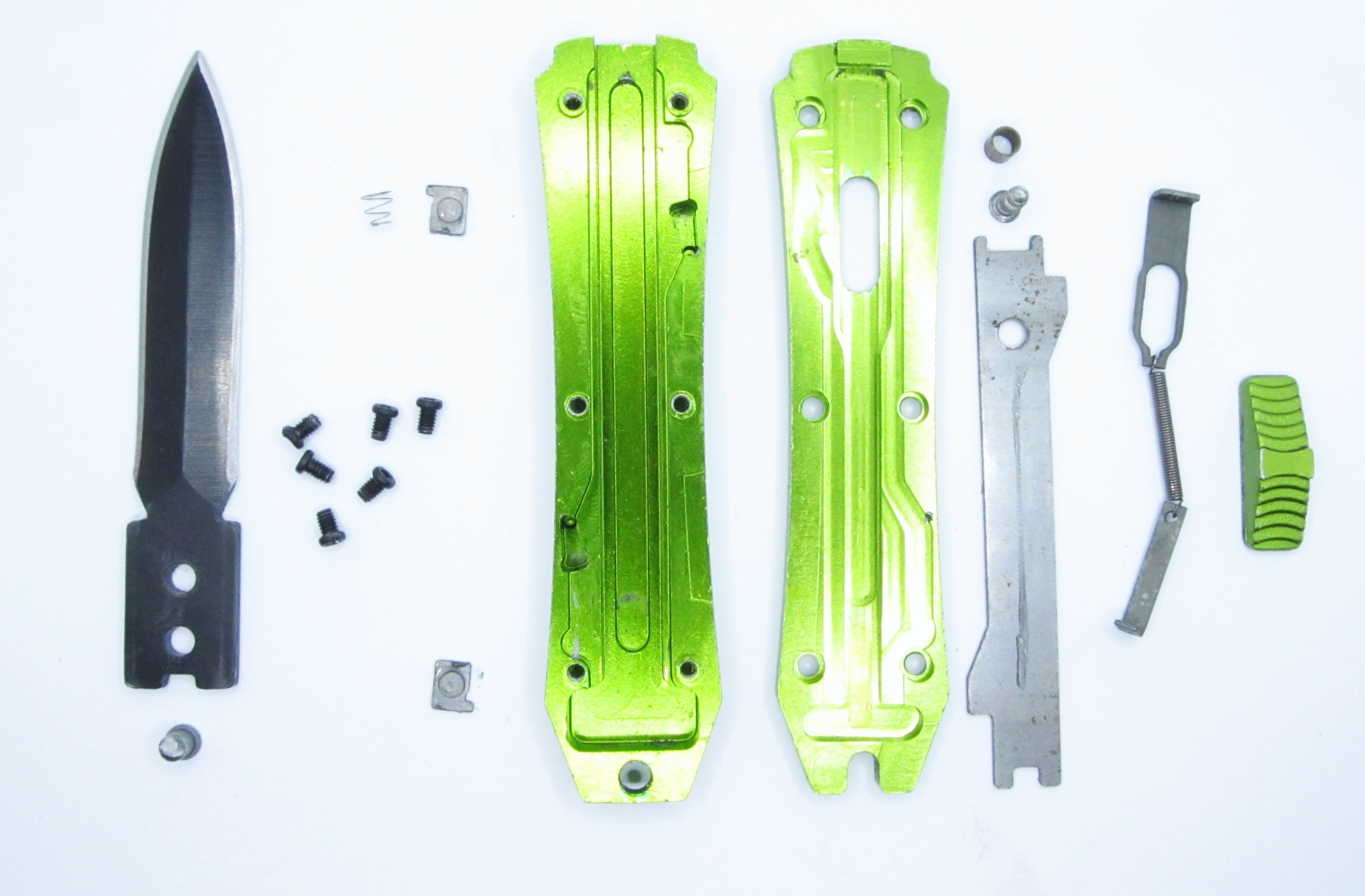

I’ll be taking this apart in two steps, here, so you can see how all the mechanical parts fit together. Both of these knives use near identical mechanisms with many interchangeable parts, so I only took apart the one.

The concept is pretty simple but it’s tough to wrap your head around visually, because there are several layers (literally). The crux of it is that there are a pair of notches in the heel of the blade that engage with those two little latches, which serve to hold it locked in either the extended or retracted position. You can see them in the left half in the picture above.

People often think that the blade is under spring tension all the time, but it isn’t. At rest, the spring is totally relaxed. These knives use a titchy little extension spring, which in the above photo is underneath the bare steel plate on the right hand half. Here it is removed:

There are two hooks in either end, one of which grabs the base of the blade for extending it and the other of which engages a little pin going through it to retract it. When you push the switch one way or the other, you extend the spring a little bit and preload it with some tension while one or the other of the little latches holds the blade in place. The switch is also attached to the steel plate, which has two ramps on it that after some travel distance hit the latches and release the blade. Now under spring tension, it flies in whichever direction – towards the open or closed position, depending on which way we’re going. The spring actually only powers it for about a tenth of its travel distance and the rest of the way it’s just carried by inertia.

When the blade is nearing the end of its travel it’ll run over the latch on that end, which acts as a one way gate. There is a tiny, hair-thin spring behind each one which closes the latch behind it, but is wimpy enough that it doesn’t rob much force from the blade as it passes by. The latch locks the blade in its new position, either open or closed, and now the spring is slack again. Then you can repeat the process in the other direction.

Here’s one of the springs. They love to ping off into the void when you disassemble the knife.

Here’s the whole shebang, in component form:

Notice the missing latch spring. I still haven’t found the damn thing, and I ultimately gave up and replaced it with a slice of a pen spring. And yes, there is surface rust all over the steel components. It just kind of did that, and I presume the plate inside is just made of plain old mild steel. It probably wouldn’t hurt to put a drop of silicone oil in these every once in a while.

The Inevitable Conclusion

For a couple of bucks, these are a neat little fidget toy that actually has some small modicum of function. I like mine, but only as a curio. I wouldn’t be in a big hurry to try to use one of these for an EDC knife, for instance.

As a significantly less regulated marketplace of made-in-China tat, Wish is occasionally a good place to get your hands on an item that is otherwise on the naughty list – Balisongs, little switchblades, vape stuff, and all the other sundries they won’t let anyone sell on Amazon. Provided, of course, you don’t wind up with something that totally isn’t what was in the picture. Or just a tall frosty glass of nothing with your refund on the slow boat from China.

I feel like knife disassembly should happen in one of those enclosed/sealed chemistry containers where you can see inside but it’s closed and you have to use gloves from the outside. No more lost parts!

Edit: they’re actually called a glove box. go figure.