So I just picked up this 12"×6"×10’ maple beam at an auction today and had to chop off two feet of it to fit it in my car. I’m thinking of making a couple end-grain carving boards for friends with what was cut off.

I’m tentatively thinking of just slicing it into 2" cookies and gluing them together, but I’ve never seen a cutting board like this that wasn’t a collection of like 1" pieces glued together. Is there any reason not to use larger pieces when gluing up a cutting board? Thanks in advance

The only reason why cutting boards are often thin is cost. A thicker cutting board will be more resistant to warping. I encourage using thicker pieces.

I don’t think I’m describing my question clearly. I’m imagining a 2" thick cutting board made up of 4, 6"×12" end grain slices from the beam.

Every end grain cutting board I’ve ever seen is comprised of many individual pieces from like .5"×.5" up to like 2"×2" at the largest.

Is checking the only risk from using very large pieces, like I want to?

Oh, I haven’t got a clue about the risks of that. I’m sorry I can’t be more help. Good luck and know that I’m cheering you on!

Something you can do is to alternate the grain pattern to prevent cupping and bowing (like what is done with a table).

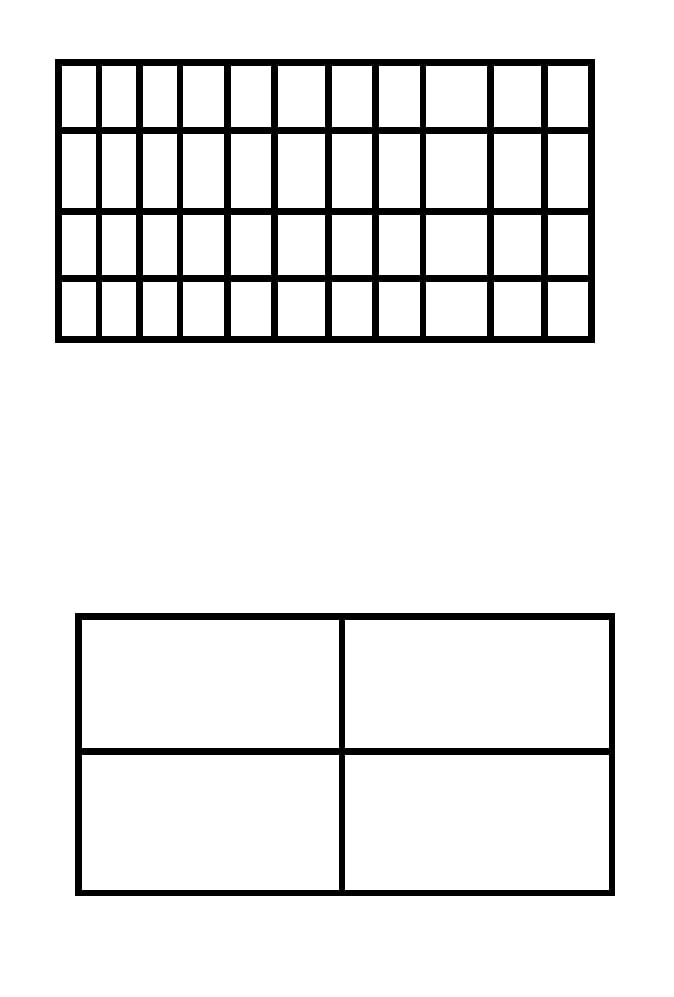

If you’re looking at the cutting board from top down (and rotated 90 degrees):

( )

) (With each bracket representing the grain pattern.

I have a two inch mahogany cutting board all one piece, it’s a nightmare to clean because it’s so big, but it looks fantastic.

I see no issue for you

Two things:

-

sick username

-

do you have any pictures handy? I couldn’t find a single image of a cutting board like I’m imagining

That’s it there. It’s kinda dirty now

I’m specifically wondering about an end-grain cutting board, but that’s really good looking!

Ah my bad, I missed that part, sorry.

-

The bigger the wood the more movement it will have. End grain boards like you describe often have their pieces oriented in opposing directions to manage the warping due to expansion and contraction. Plus the more pieces the more glue jointing holding it together.

To provide more stability, you could cut a series of slices and flip every other one such that the curve of the grain is alternating.

Like, instead of one, large 2" slice, two 1" slices, rotated 180° relative to each other?

I think we’re saying the same thing?

You have your end grain slab laid on a table in front of you. From left to right divide cut it into parallel pieces (width of these is up to you 2" or 3" is probably fine). With them all laid on the table on their original pattern, rotate or flip alternating slices. Glue it up.

I bought my edge grain cutting board there. They have 2" versions as well as up to 6" versions (https://www.holz-liebling.de/produkt-kategorie/schneidebretter/hackblock/) You could look at their pictures to get some hints at what you could do.

I think this has been somewhat alluded to but you will be more stable with smaller pieces. First it increases the overall glue surface in the piece. End grain is somewhat fragile so depending on how your friends use them it could be a problem with bigger pieces. The other thought is overall aesthetic. I’m wondering if it will look weird if you have larger end grain pieces vs smaller. Not sure either way but worth looking at. You could dry fit with larger pieces and if it looks funny then just cut them down to a smaller size.

I was at an American festival here in France last week, and there was a stall selling ghastly glued-together cutting boards. It’s not something you see here normally.

I’m convinced Americans are missing huffing leaded petrol fumes all day so now they’ve taken to consuming vast quantities of adhesive scraped from their chopping boards to ensure their daily quota of brain damage