This Microchip.com article talks about a new feature of VQFN packages being pushed by the automotive industry.

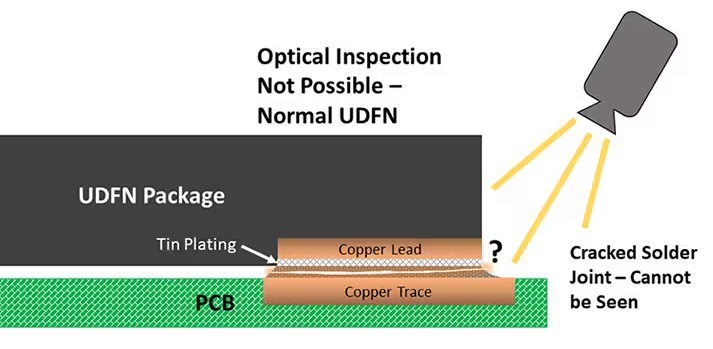

VQFN packages are normally very flat with “invisible” solder joints under the chip, rather than around the chip. This means that VQFN packages need to be X-Rayed to see the quality of the solder joint.

The automotive industry didn’t want such an expensive X-Ray machine for inspections however. Recently, it seems like an obvious cheap solution has been popularized. The Wettable-flank.

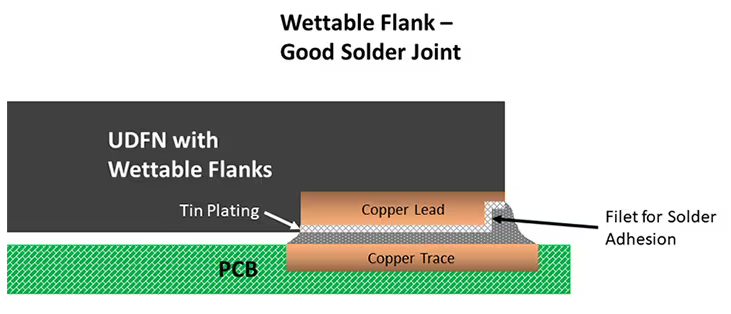

By creating a “notch” on the edge and creating a tin-plating along this notch, visual patterns emerge for good soldering joints in practice. All of a sudden, VQFN packages can be inspected using nothing more than a typical magnifying glass / loope. No more need for X-Rays.

I’m beginning to see more chips with this feature. This is great! It means that its even cheaper and easier to reliably use the tiniest VQFN packages in practice today (well, BGAs are smaller, but those truly require X-Ray inspections).

Those who wanted visual inspections are no longer trapped on the larger TQFP packages anymore. With wettable flanks, the smaller chip is probably far more usable!