The part is a 345mm x 60mm spice rack that mounts to the inside of our pantry door.

About 7 years ago, I made four spice racks out of wood and painted them to match our cabinet door. Wear and tear (and kids) have resulted in them getting glued back together multiple times. I finally gave up, modeled the design, and have been printing replacements in PETG as they fail. So far they’ve been holding up a lot better. They’re also a touch deeper than my original wood design, so they can fit the round spice island containers more easily.

In the past, I had to print these in two halves on my i3 clone (a Monoprice Maker Select Plus, which is a rebadged Wanhao Duplicator i3 Plus). Now that I have a printer with a 350 mm^2 bed, I thought I would see if I could print the rack in one piece. My single ASA attempt was an epic fail due to warping, but the PETG print went very smoothly with very minor lifting. I’ve read others say PETG does not like enclosures, but I’ve printed a number of PETG parts with my Voron fully enclosed and they’ve come out very well. I struggled with PETG warping on larger parts with my unenclosed i3 clone.

Here are a few photos comparing a rack I printed on my i3 clone to this one. The print quality is quite a bit better, but now that I have a higher ceiling to shoot for I’m realizing I have a further to go on my tuning journey. I will say that I never noticed things like the Slic3r buldge, that’s also present in Super Slicer, until now.

I personally find it helpful to see other’s prints under unflattering lighting, so with that said…

Somewhat flattering lighting (eg ambient)

Voron:

i3 clone:

Direct light, provided via a flashlight, perpendicular to the surface

Voron:

I3 clone:

direct light, provided via a flashlight, nearly parallel with the surface

Voron:

i3 clone:

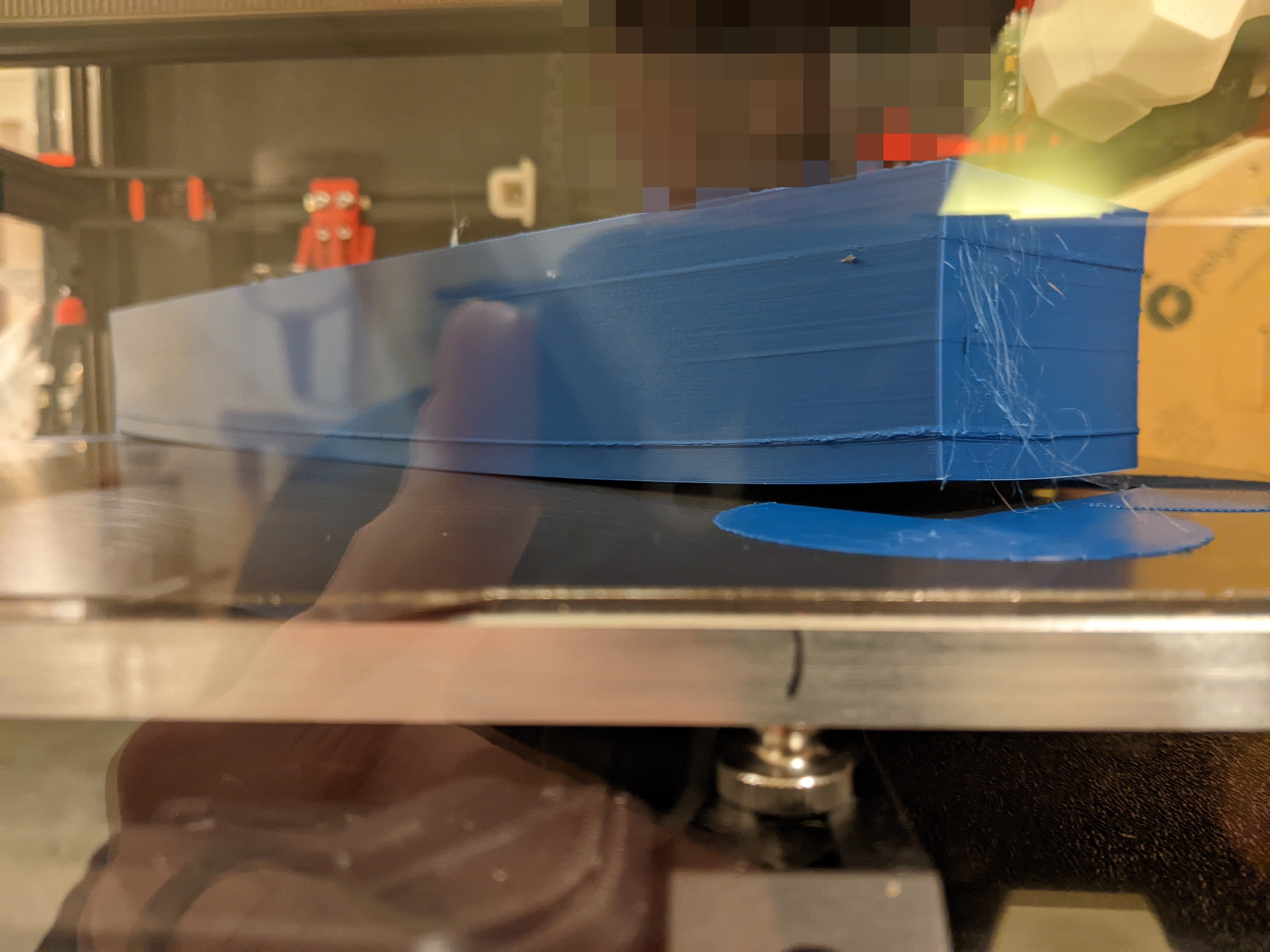

Bonus photo of my ASA attempt

Sadly, I forgot to change my print temp back from 250 to 240, so there’s quite a bit of wispy stringing. I suspect the print would have separated from the bed anyway. Any pointers here would be appreciated. The bed was clean (soap + water), was at 100, I let the printer heat soak for about 45 minutes with the filter going full tilt, first layer squish was solid good, smooth PEI (the textured side seems to have prints come loose more easily).

What chamber temp are you using for such a large part? I’d recommend at least 70+C but that might be hard to reach with acrylic panels.

Your bed will also warp due to the heat since its rigidly mounted.

For the black PETG part I doubt it got that hot, but I’m sure it was above ambient by 5-10 degrees C. 70 degree bed and my filter/bedfan combo at 30 percent.

For the ASA part, I let the printer soak after the bed hit 100 C with 100% bed fans. I’m not sure what temperature the chamber reached due to not having a thermostor.

Do you think the ASA print would have succeeded with a hotter chamber? If yes, I’m all in on adding some more bedfans, a chamber thermostor, and swapping some panels for better insulating ones. I’m trying to figure out if there’s a wall to what you can reasonably expect from ASA or if there’s still some low hanging headroom that could be unlocked with better heating.

ASA and ABS definitely do better at elevated chamber temps. What temp is enough I can’t say but I still saw improvements when going from 50 to 70c. Higher temps also let you use more fan speed without the added risk of warping so you’ll probably see better overhangs even though the temps are higher.

Id start with adding some chamber temp sensors first so you can measure what difference you are making with the other mods.

Using 4 mm abs panels I saw about a 15c improvement by just throwing a fleece blanket over the printer, so that might be an easy fix if you don’t print large parts frequently. Although higher temps are also great for layer adhesion on smaller parts.

Thanks for the feedback. I’m thinking a mix of thermostors, two more bedfans, and better insulation is my next step for less ASA warpage.