I’ve been chasing inconsistent top layers for a little while when my first layer also started going… very sideways. My printer uses the nozzle to home on a micro switch, which meant that something was probably loose. Initially I was thinking the end stop or carriage, but who would have thought that the printer had shaken the hot end apart over time.

Note to anyone else who runs into this: there is no mechanical stop for those screws and tightening them too far will mash the hot bits into the cold bits. This will cause the hot bits to crimp closed just enough to no longer let filament through. If you find yourself in this situation, find (or buy) a small punch - you can use the taper on a punch to reverse the situation. Don’t ask me how I discovered any of this. Why there is no thread lock from the factory, who knows. If anyone reminds me, I’ll be sure to let you know how well purple loctite has held up. There’s also another screw that goes into the side of the heat break to hold everything in place. That one was loose too.

2.5 hours later: all better!

Lessons learned: multiple, but if you start seeing inconsistent behavior look for a mechanical issue and don’t be afraid to tear your printer down.

Awesome, you found the problem!

Any before and after pictures of builds, and of problem area?

Thanks for sharing!

Thanks!

Are you looking for prints that were of varrying degreea of quality, the printer itself (it’s a Voron 2.4 so there’s a decent build behind it), or what the hot end should look like when properly assembled?

Yes, before and after pictures of quality prints, if possible!

While also showing an updated picture of what you posted!

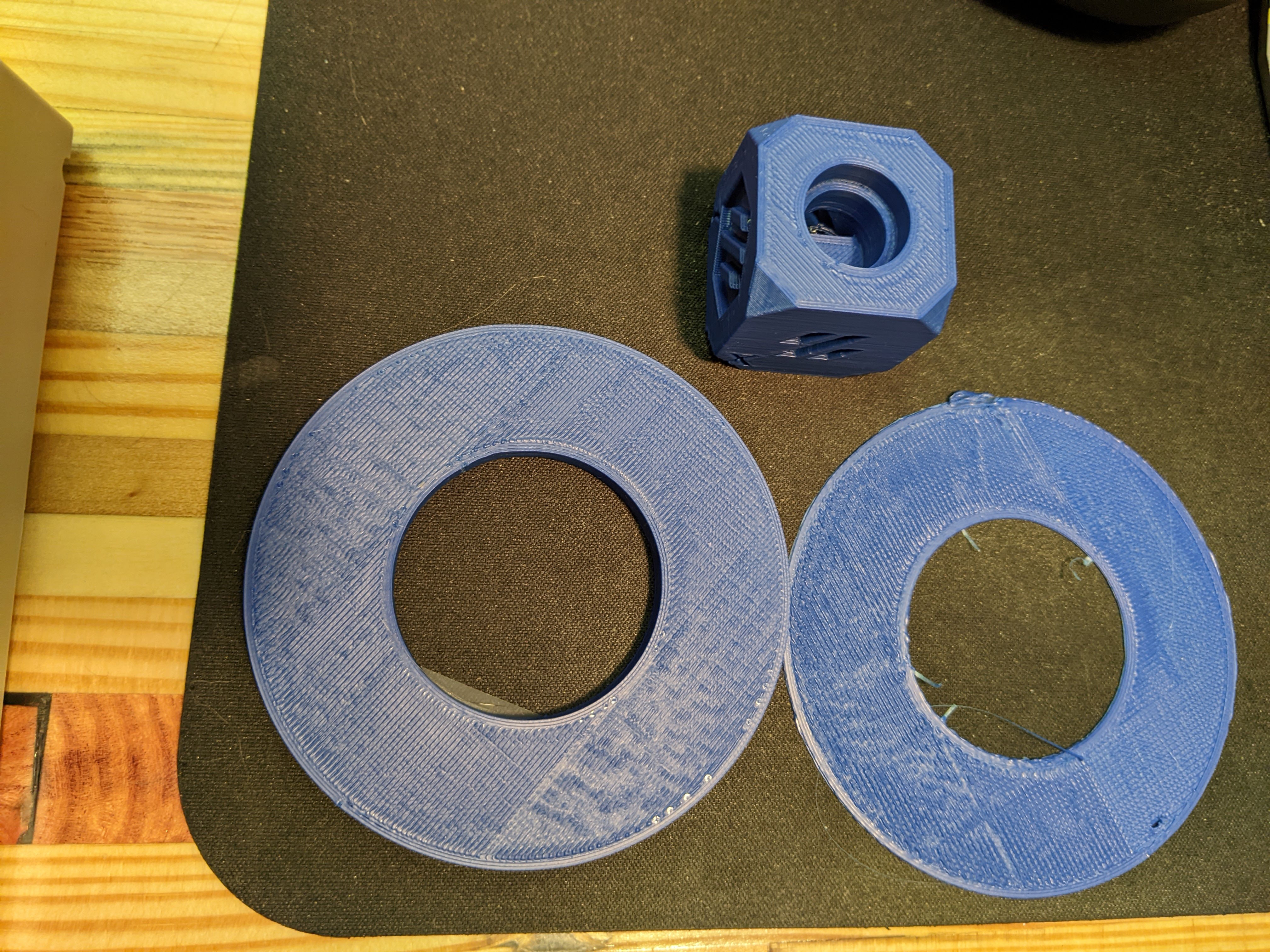

Here are two before and one after. Lower left = top layer over extrusion, but the bottom was fine. Lower right = that’s only 2-3 layers in total, but since it was way too close to the bed it was rippling like crazy. The cube = hot off the press and looking pretty good.

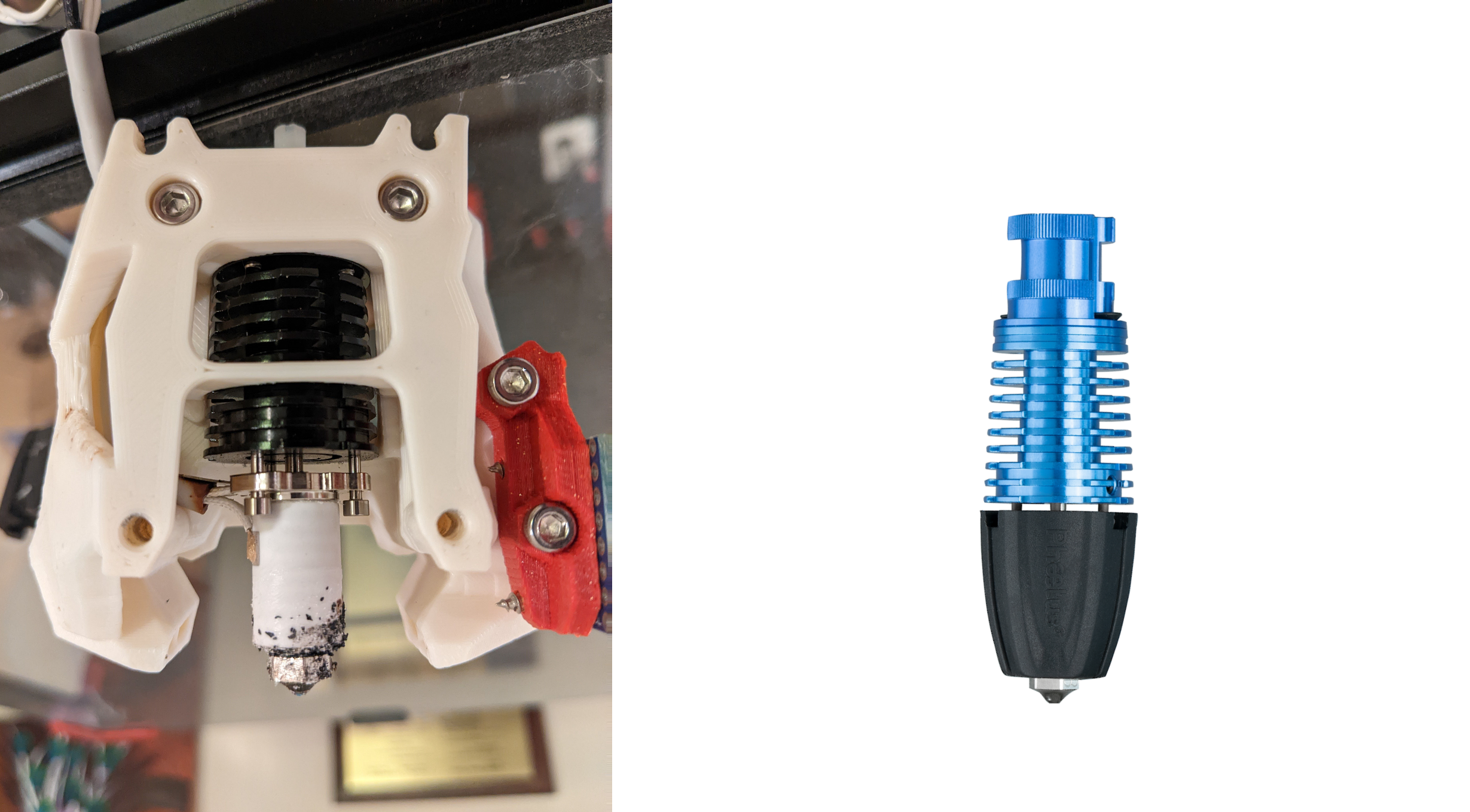

I didn’t take any fixed photos of the hot end, but this page has a number of pictures showing what it should look like (look at the three screws if you didn’t see them sticking out in my earlier picture).

Wow, great picture!

Thanks for the link, I did a quick comparsion of your pic and the one in the link:

Thank you for taking the time to show us your print problems and explaining!

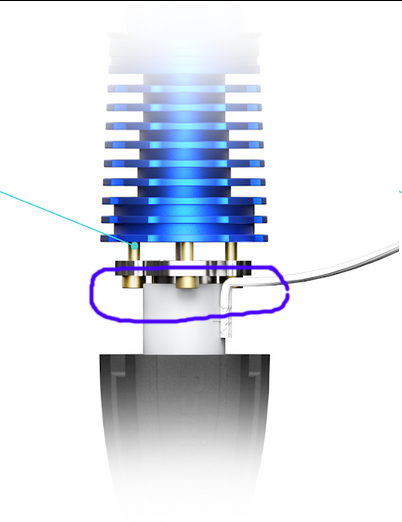

Happy to help! For a little more context on the pictures: the hot end is available with blue and black anodizing. I have the black version (mostly because that was what was in stock). In my photo, the back silicone sock has been removed. Here’s a better photo, also from the linked page. I’ve circled the three screws I’m talking about.

Ah, I knew I was missing something in the picture!

Thank you for pointing that out!

Is threadlocker usually resistant to high temperatures? If not that would explain why it doesn’t come from the factory.

Threadlocker is often used in automotive applications, like engines, but an engine rarely exceeds much above 110 °C. Looking at the datasheet for 222, it’s rated for 150 °C, but it does look like it loses strength as it warms up and it also starts to break down above 120 °C.

I can’t see it hurting, but it might not be as long term a fix as I had hoped. If it comes apart again, I’ll have to try 272. It’s rated for “up to” 232 °C.

I am very curious how hot the heat break actually gets.

Interesting, if you’re using it for the cooler part of the heat break then it should be a lot cooler since that’s what the heat break does.

It might not hurt, but if I had to imagine a scenario, I’d say it could break down and create carbon deposits that could act like graphite powder and lubricate the screws. I guess time will tell ¯\_(ツ)_/¯

That would be a truly amusing outcome, lol. You’re right - time will tell. But thankfully at least I’ll know what to look out for this time around.

Red loctite on fastners that small has a recipe for being a bad time if it sets up proprly, I find some of the small screws around the hotend can already be prone to stripping due to things like plastic buildup thats hard to remove.

At least on the dragon, theres a sizeable gap between the inner and outer portions of the heatbreak and some distance between the block and the heatbreak, I’d be surprised if the threads get hot enough to worry about even without the hotend fan.

Thanks for the intel! Here’s hoping that the purple holds.

New Lemmy Post: Well there’s your problem (https://lemmy.world/post/13232494)

Tagging: #3dprinting(Replying in the OP of this thread (NOT THIS BOT!) will appear as a comment in the lemmy discussion.)

I am a FOSS bot. Check my README: https://github.com/db0/lemmy-tagginator/blob/main/README.md