Senior Airman Devon Word, a conventional munitions crew chief from the U.S. Air Force’s 48th Munitions Squadron, solved a perennial ammunition handling issue faced by the 48th Fighter Wing at RAF Lakenheath, U.K., which often saw 20 mm rounds jamming while moving from the replenisher table to the ammunition loader. The frequent jamming makes manual intervention necessary, with “15 minutes of troubleshooting per jam” required which “may also cause injury to the operator.”

In fiscal year 2023, according to the press release, there were 319 operations resulting in an average of 957 instances of jams using the replenisher table. These accounted for approximately 798 man-hours due to the need for at least four personnel during operations.

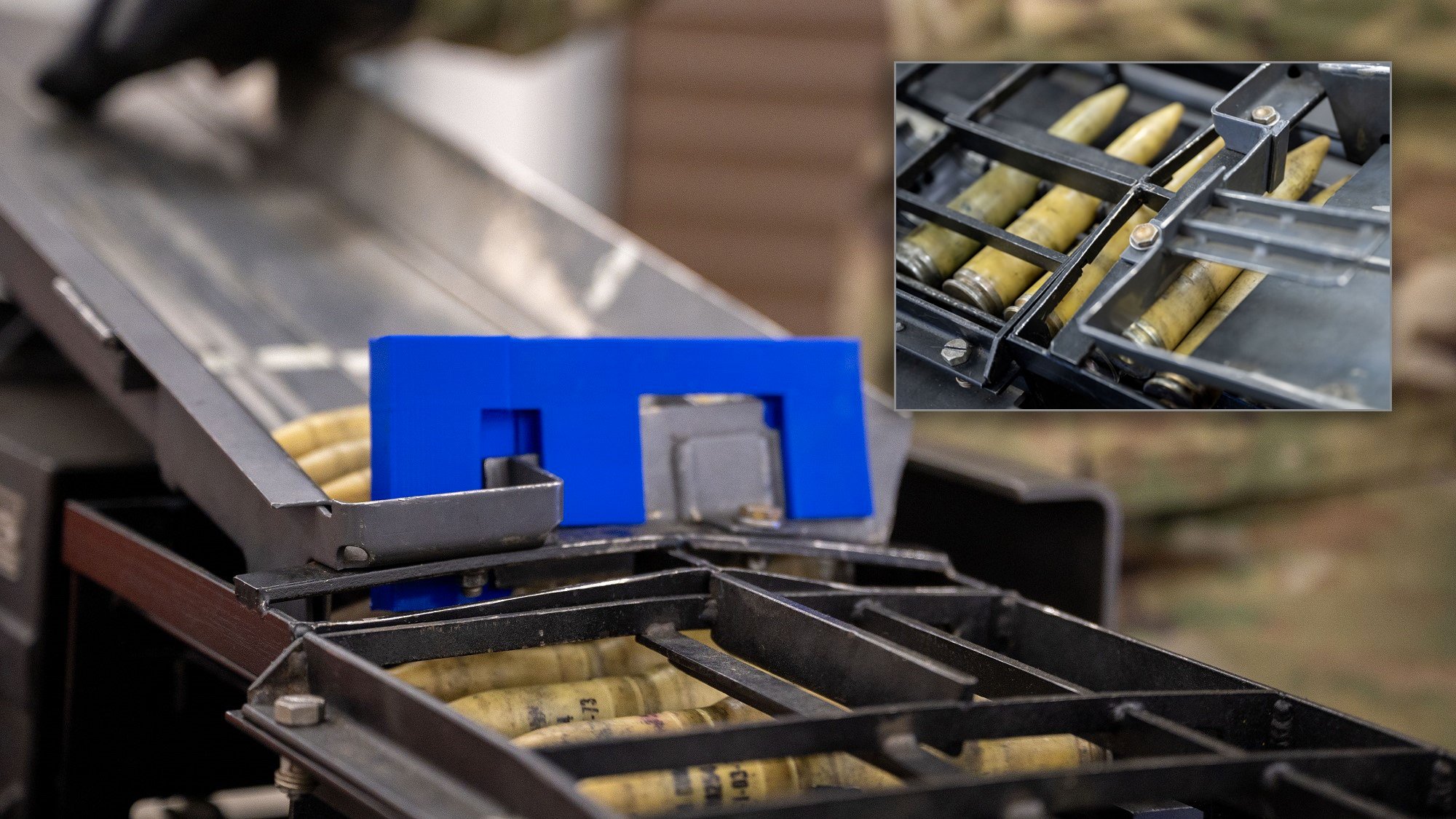

Word developed a specially designed 3D-printed insert that addressed the old design issue causing the stoppages – a gap between the rounds and the top of the replenisher table. The unit-level innovation could save the 48th FW and U.S. Air Force over 750 man-hours annually, the unit said.

…

The Air Force has a program to support just this kind of innovation. If they allowed a media outlet to come in and do a story you can bet this had been approved all the way up the chain. This dude probably just earned some official reward bucks, too

Should have had his wife “design and print” them, get a patent, and sell them to the air force instead.

This guy defense contracts.

Service disabled Veteran-owned, woman run small business designation coming to an Etsy shop turned DoD contractor near you.

$3,999 per insert for probably $0.75 of filament. Any less is an insult to the MIC

Facts

I meant that keeping it a secret isn’t a real option.

But yeah it’s nice to see people encouraged to do in house innovation! The military can have a ton of red tape and people that would rather have you embrace the suck than reduce the suck because it’s less work (for them). Imagine the BMV running everything and you get the idea lol

I see your point