- cross-posted to:

- [email protected]

- cross-posted to:

- [email protected]

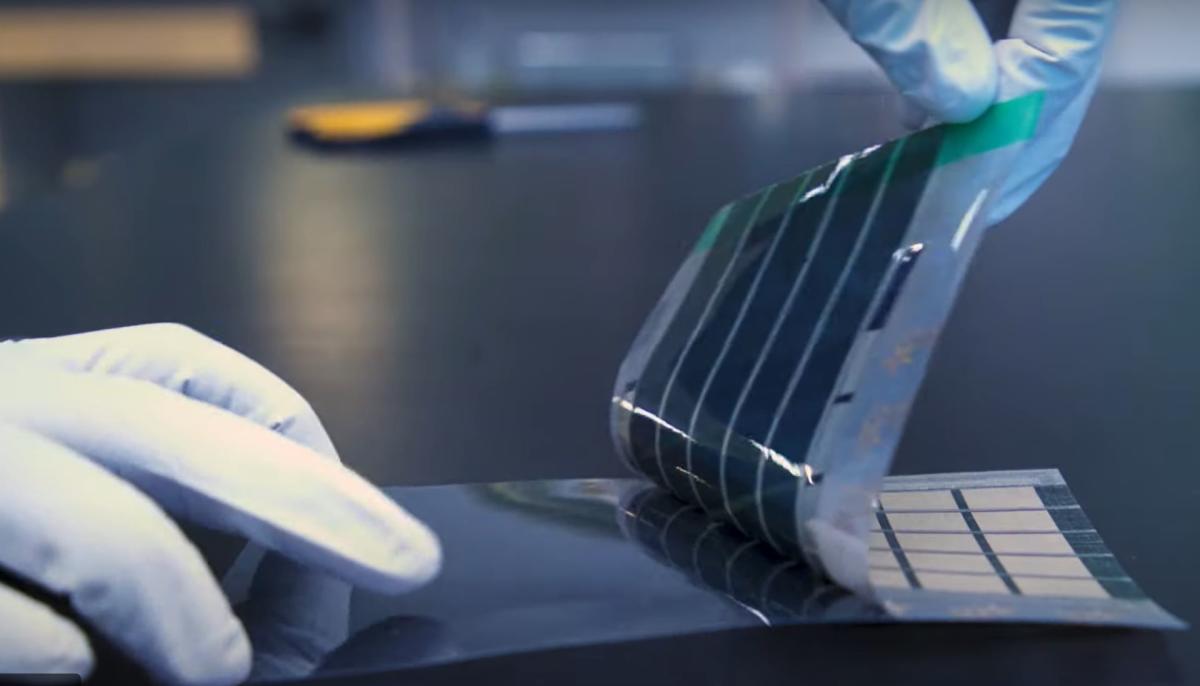

Scientists develop mega-thin solar cells that could be shockingly easy to produce: ‘As rapid as printing a newspaper’::These cells could be laminated onto various kinds of surfaces, such as the sails of a boat to provide power while at sea.

It’s a different process. Multiple processes with varied applications are absolutely essential to making this style of solar the norm

It’s a great thing that this particular field continues to see innovation.

New process

Your linked process:

Ok thanks. I see the difference. It was a late night knee-jerk defensive post.

As a fabric geek with a cut/sew shop working on marine canvas, this gives me a raging boner. The panel making process might be cheap but I’ll tell you dyneema fabric isn’t. Bet there’s great mark-up on it though! 🤑