- cross-posted to:

- engineeringmemes

- cross-posted to:

- engineeringmemes

Then you find out that the lack of an ingredient results in the microbes producing the product lol.

Certain algae for example, need to be “starved” in a way that results in them switching from conventional photosynthesis that produces glucose to photosynthesis that functions to generate Hydrogen and Oxygen alone. The Oxygen is used for respiration and the Hydrogen is essentially dumped as a waste product. They can only sustain this for relatively short periods before their stockpile of carbohydrates is sufficiently depleted. Which means these bioreactors need to be cycled through a fattening phase where the algae stockpile fuel and a starvation phase where they exhaust that stockpile while producing Hydrogen.

Stop algae cruelty

Phycologists on revolt.

Fuck them eukaryotes

Well the alternative is us setting the solid, liquid and gas remains of their ancient ancestors on fire which slowly makes the planet uninhabitable.

Wow, could you point me to any resources where I could learn more? I’m doing undergrad biochem…

Nitrogen starvation increases Hydrogen yield: https://pubmed.ncbi.nlm.nih.gov/402109/

Sulfur starvation doing the same as well as a strain that doesnt need to be starved: https://www.sciencedirect.com/science/article/abs/pii/S0360319920341550

How did you come across these?

Ive been trying to keep tabs on the literature in biochemistry, chemistry and other fields for decades. I inevitably come accross things like this from time to time. These particular articles I just googled because I dont have the bookmark for the original paper discussing Hydrogen production back in 2000.

That’s the problem with the biological.

It’s even better with software because you can tell the computer exactly how to do the wrong thing.

And then blame the computer.

I’ve given you sunshine.

I’ve given you dirt.

You’ve given me nothin’

but heartache and hurt!

I’m beggin’ you sweetly.

I’m down on my knees.

Oh please,

Grow protein!!!

me when i fail the assay i almost singlehandedly designed

it me

today

F

Hmm object to the average chemical engineering work. We are mostly fancy plumbers, so we end up just sizing pipes and piping systems a lot .

So, is it literally just repeatedly creating the necessary conditions and hoping the stuff will react the right way? Or is it a strict process that needs to be done just so or it’ll ruin the whole thing? Or both?

Biochem is incredibly sensitive to seemingly minor changes in conditions or procedure. A former coworker of mine had to change careers after the procedure she had to follow to run the assays for her master’s thesis gave her severe RSI. She couldn’t alter the procedure for ergonomics, though, because even something like changing the angle that she held the pipettor at could throw off the results.

In biopharma work, it’s not at all uncommon when trying to manufacture a biologic to find a process that works reliably in the lab but doesn’t give the same results when scaled up to production-size bioreactors, such that there’s often a whole stage of R&D devoted to taking a procedure from the lab and reproducing it on successively larger pieces of equipment, while working out all the tweaks and adjustments needed to make things work and optimize production.

Fascinating. Do you know any good resources where I can learn more details like this? I’m doing undergrad biochem rn…

Alas, my knowledge on the topic is limited – I work as a lab planner, and what I wrote above is most of what I’ve gleaned over the years of designing process development and scale-up labs. Past a point I just ooh and aah appreciatively at the big robotized bioreactor arrays my clients are putting in. Hopefully someone with a deeper background can point you in the right direction!

Yeah, kind of a little bit of both. Assuming that this is about bacterial transformation, it kind of goes like this in the lab. It’s from 2012 so there are probably easier techniques with fewer steps.

And these (11:00-16:00) are the basics about bacterial transformation.

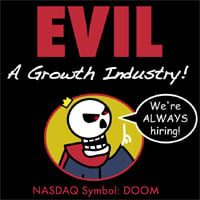

This meme didn’t show the revolving lab door, the giant corporate foot over the biochems head and the minimum wage employee who makes more money than them.

Biological life be like: ahaha entropy go brrrr