A few more parts for a Voron Trident build

Here is an alternative Piped link(s):

Piped is a privacy-respecting open-source alternative frontend to YouTube.

I’m open-source; check me out at GitHub.

A headphone hook for my desk… which I should probably take off the list cuz I just bought one.

Ender 3 is more of a project and less of a tool. Hoping to get a Prusa, everyone always remarks on its amazing reliability.

You say that, but after my last set of tuning my E3 Pro is a real workhorse! Give it another 4 years like I did. May also help to threaten it with replacement if it fs up ONE MORE TIME…

When I was fixing up a CR10s to give away (it was a rescue from another friend that fucked it up and then gave up.)… I would show it the old Univac manuals with instructions on where to hit the chasis, and tell it I was in conversation with Creality about the proper usage of hammers.

Seemed to work…

Huh, my Ender 5 cranks out part after part with almost no fuss and has for years.

I think I just about dialed in a profile, but I’ve yet to get to a place where I can just hit print and get a thing. Tinkering with it was fun for a minute, but i want a system that just works. And if that means buying a prusa printer, with prusa slicer, and prusament I’d be more than happy to go that route. I want to focus on what to print, not how. At least not now, I could definitely see me getting into it more, and then wanting to eventually do more complicated stuff requiring customizations of hardware and software, and materials, but it’s hard to get in the mood to go deep when struggling to do the basics.

I use PrusaSlicer and their Ender profiles with no tinkering and get consistently great prints.

I got the 5 a few years back. Great printer but I didn’t like the bounce in the platform so I printed stabilizers. Didn’t like the placement of the extruder moved it up top. Added the HeroMe. Still didn’t like the bounce of the plate so added a second z-axis. Added direct drive extruder. Linear rails. SKR mini. AC bed heater. Klipper. Mosquito Magnum. Prolly some other stuff. About the only original parts are the frame. I used it to learn how to print. And I printed some great stuff along the way. But it’s good now. I pretty much just print. But I really like that Bondtech LGX. Might have to try that out. :-D

The Printer of Theseus.

Lower cost products sometimes have more variability and maybe you got a good one from the factory.

Mine does too now. But I got a bad batch of pla and I could have sworn the sender was the shittiest printer on the market. It was off line for a year before I tried again. I recently switched back to that old roll because I wanted the color, and that shit peeled up and warped to hell again. Now I know for sure that spool of PLA is bad

there’s always those upgrades to the printer.

R/C parts- a back burner project is a cyclogryo. (The hope is to eventually build a hoverbike vaguely similar to the malloy hoverbike.) and there’s a few other things I need to print to get some models back to flying.

I’ve also got a chess set I’m working on- inspired by a set of files that are inspired by a metal set made by [Charles 'O Perry]9http://www.charlesperry.com/puzzles/chess-set). But that’s a backburner design, in part because they’re still enjoying the Lewis chess set I printed (in iron and bronze metal fill PLA,)

then, I’ve got a lot of requests for pendulum clocks from people I know. but those are a fair amount of assembly work as well as printing time. so they tend to be only for people I actually like.

Just about everything i wanted to print, still.

I’ve reached the point where i should just surrender my ender 5 plus and all the mods, just buy a bambu lab or something that actually works well from the factory.

Ew no. I’m still on my ender 3 pro version 1 from 2019. It’s upgraded to the teeth and works great.

There’s no way I’d throw away all that work for a locked down corporate spy machine that uses lots of proprietary, nonstandard parts.

I’ve had mine for 3 years, 3 years of headaches and modifying and it still doesn’t work right.

I tried printing something huge, turns out one cormer of the bed doesn’t warm up enough. It also has started having these uneven layers as if the belts aren’t at the proper tension.

It’s been 3 years of solving issue a and getting issue b, to solving b and getting c etc. Neverending maintenance and zero usability.

And how much more have you spent on upgrading it than it would have cost to get a prusa or built a voron lol

Maybe $100. Almost all of the upgrades were printed. I bought an all metal hotend and a glass bed. I think that’s it. Probably more like $70.

I have a few mechanical keyboard projects that I need to print cases for and a chassis for a compact NAS build that I’m almost done tweaking and need to print eventually. Just functional stuff really

Love :(

yay

deleted by creator

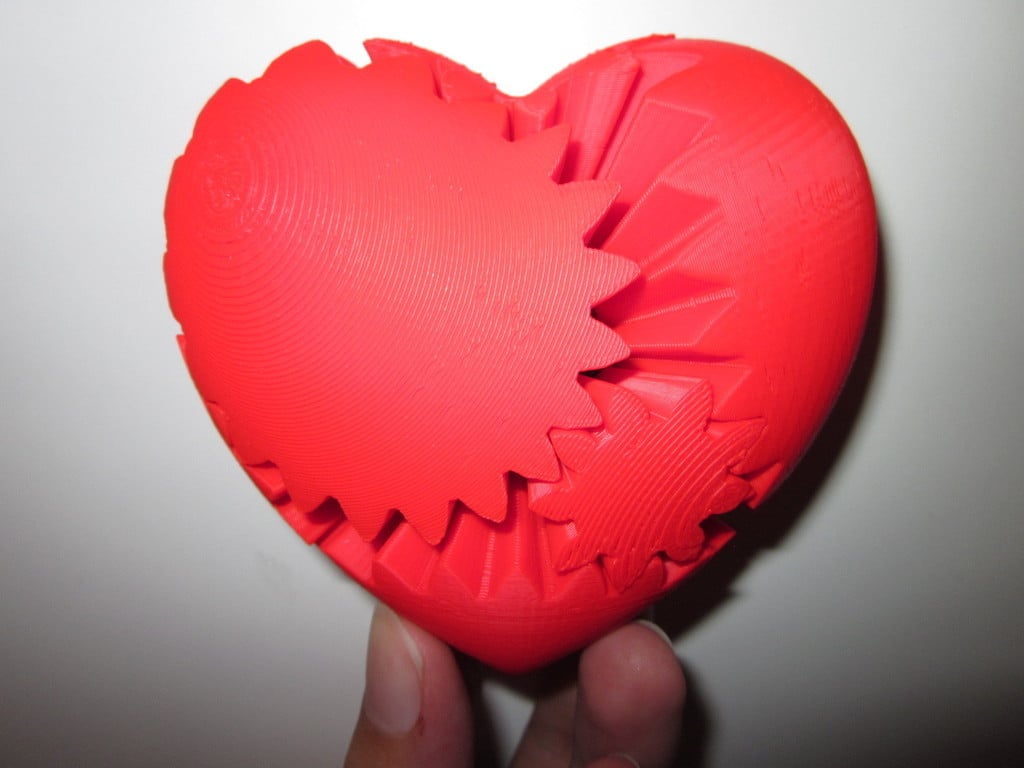

Those gears will never turn in that configuration. This clearly proves love is a lie.

deleted by creator

This clearly proves that love can be unpredictable!

Boats. Lots and lots of tiny boats.

2 new dresser legs, a handle for a dryer.

Pretty much replacement parts for things around the house as much as possible.

I am even in the process of printing replacement parts for the 3d printer as well as backups in the event something breaks.

A lot of organization - tool organization for the garage, drawer organization for the kitchen and bathroom, wall mounts for things all over the house, some display shelves for lightweight things, crafting supply organization for my partner and also charging docks and headphone clips for VR headstrap.

3ds stylus

I had printed some accessories for my Quest 2 before, mostly for the controllers. I’d like to print them again, but 90% of them connected onto the rings that the Quest 3 controllers don’t have so they need to be re-engineered and I just can’t be arsed.

Tbh things I design. It’s so much more fun!

yup, being a lifelong 3d modeler, being able to print my designs is exceptionally satisfying.

Do you have any noteworthy examples, or which on ones are you most proud of?

Here’s the stuff I’ve shared: https://www.printables.com/@aeharding_167804/models

Nice! I like that mike mount, looks clean

Antidepressants

Have you tried the PLA flavored ones??

Replacement mouthpiece for a vintage flute that had a plastic one.

Flute pad hole punch aimer thingy so I can make cheap China pads into open-hole ones for not-so-great flutes without having to buy a bunch of open-hole ones (version 1 was already made and proved the idea, now it’s just to iterate).

E facilitator prototypes before I CNC them (still learning CNC and I don’t like it).

Flute airstream aimer clip-on thingy for older people who have lost their embochure due to dental operations and such. (after I get the hang of the replacement mouthpiece; this is probably the most difficult one, due to precise mouthpiece shape needed)

Model for manually engraving the right size & shape replacement piece out of bone, for a badly cracked teapot.

Spherebot.