While this is an obvious/facepalm miss, the protective boot is not a part of the RJ45 specification and is not required for the cable to function in any way. It’s only there to protect the plastic tab from being bent/breaking too easily.

In a data center environment, that’s less of a concern, as it’s just more unnecessary waste/space taken up as well. Most cut the protective boot off or buy cables without, because that boot gets in the way of more than just this router design.

Again, while facepalmy, this isn’t as bad as it seems at first glance.

The protective boot is still quite useful in a data center environment. It makes it so much easier to pull the cable without it getting stuck absolutely everywhere.

I believe it wasn’t even on all of them

The identical badge-engineed Buick Skyhawk, Chevy Monza, Pontiac Sunbird, and Olds Starfire of the '75-'80 model years were equipped with a 3.8 liter V-6 that was very large for the size of the engine compartment on these small cars.

The result was that, in order to change the spark plugs on the right bank of the engine, you had to disconnect the motor mounts, attach a chain hoist, and lift the engine at least a few inches in order to be able to access those plugs.Laughs/cries in Subaru

Ya, tell me about it; I have 2 Crosstreks.

I’ll never forgive myself, nor be forgiven.

Dont worry, GM never learned their lesson. I remember having to do that on my mom’s Chevrolet Venture minivan…

I’m pretty sure some 2000s Renault models had it so the only way to change the front light bulbs was through the wheel wells

I had a Honda like that just a few years ago. First turn the steering away from the bulb you were changing, then practically lie on the floor, reach up into the wheel well, through a hole and find the edges of the protective boot around the light. Use your fingernails to pry it open, then, blindly try to get the electrical socket off of the bulb. Once you had bled enough, and the car accepted your blood sacrifice, the socket would pop off and you could work on twisting the bulb loose. Did I mention you’re doing this whilst up to your elbow in the car? Your wrist is already locked into an unnatural position, so you’re twisting with just the force you can generate with your finger tips. Eventually the bulb comes loose and you bleed some more as the back of your hand hits a hidden edge. Carefully extract your mangled limb, clean the worst of the grime off of your fingers and grab the new bulb. You’d better hope you remeber exactly how to get back to the back of the light fitting because blindly poking around with a glass bulb will end poorly. Eventually you find the hole it fits in, and muttering a prayer to any god that happens to be listening, give it a twist. It spins but doesn’t lock. Keep trying with cramped and aching fingers until it finally slots in an locks. Silently weep as you realise you can’t find the cable anymore. Somehow rotate your wrist 180 degrees and feel it where it’s sprung just out of reach. Jam your arm in deeper and grab. You’ve got something! Now, carefully feel your way to the socket at the end. Be careful not to let go or it’ll spring away for another game of hide-and-seek. Carefully manouver the socket over the bulb and push it into place. Don’t twist or the bulb will come loose and you’re back to square one. Is it connected? There’s no way to tell except switching it on, and you’re still elbow deep in what could be a medeval torture pit. Decide to push on. Find the edges of the protective boot and fight it back into place. Extract arm. You’re not sure if it’s shaking from being so contorted or from blood loss, but you look at the sky and see the sun is dipping towards the horizon. You started what you thought would be a ten minute job in the mid afternoon. You realise you still have the other light to change and try not to give up all hope. Only the thought of your family waiting for your return keeps you going. Turn the steering wheel the other way, muster your remaining courage and plunge your other arm into the hungry depths of the maldesigned monstrosity to repeat the process, this time with your non-dominant hand. No matter how hard you try to stop them, curses that should by rights blister the paintwork slip from your lips. Finally the job is complete, and you get to admire the matching wounds on your arms by the light of you handywork. Retuen inside, mop up the worat of the blood and collpse in bed.

In many respects it was a well designed car with clever features, but that bit was atrocious.

This, but a VW Passat. Easier to just take the whole front end off to do a bulb change.

That reminds me, I’ve torn the whole thing apart but I CAN NOT find the spark plugs in my new VW

Is it a TDI?

ID.4

Did you check beside the carbureter?

I can’t even find that

Many of their FWD V6 vehicles had this asinine fate.

Good god I can not stress enough how everything Cisco makes is just dog shit in terms of physical standards. A TV screen where the power cord plugs in to the bottom and there’s no route for the cable to go back up to where your electrical outlet is behind the TV, also using a power cable that sticks out of the wall farther than Cisco mount holds the display off the wall, so it’s crushed forever and always.

Oh a meeting room control? Let’s make it 1 1/2 rack units tall, so it leaves a massive gap into the rack from the front.

Touch panel inputs that you have to break the stand off to get to.

Cisco is just a fucking nightmare.

This probably does not apply to the Cisco rack hardware you mentioned, but odd rack units does serve a purpose: I was part of a group designing some proprietary hardware for our company, and I suggested 1.5U height on puprose: That way whoever installed it would be forced to leave a gap over it, because that’s where the air intakes for the fans were.

If you’re doing that, just make it 2U and direct the inlet from the front so that we can have proper hot and cold aisles!

Front and back was occupied by other hardware. The innards came with some design constraints.

Sure, but you had the extra 0.5U that you’d left as a gap. Run the airflow through that, but don’t make it just a gap or you end up with hot air flowing back to the cold side.

I’m not trying to reengineer your product, Ive just had enough frustrations with rack mount hardware to make me cranky if it isn’t just the way I want it!

Cisco make TVs?

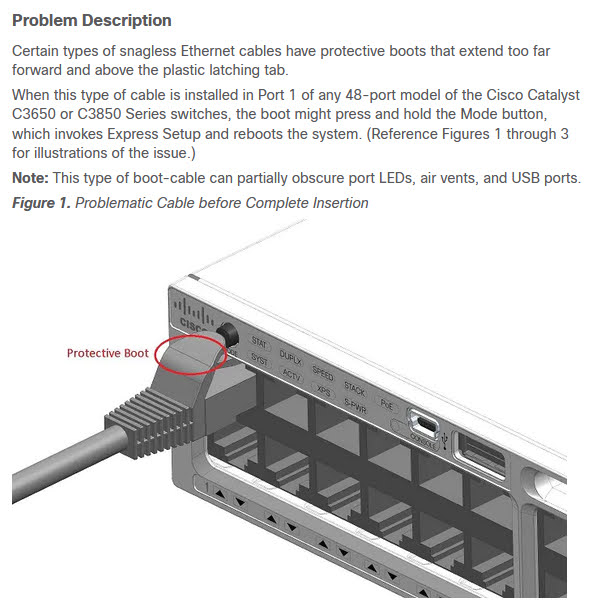

How did that not get caught in the prototype stage? Like, did nobody ever test that thing with that type of RJ45 plug?

Because making shit / design isn’t as easy as most think. You think of a million things and then the millionth-and-one screws you over.

Early in my engineering career, I was told that a screw hole on a part needed to be increased one size. Not knowing any better, I increased the size but made the thread count the same. Little did I know that the machine shop head had recently gotten unfairly grilled by management about following engineering drawings to a T, and had adopted an attitude of malicious compliance. So rather than reach out to engineering to check if they really needed this obscure thread size, he instead just went ahead and purchased a new $7000 threading tool for that size that would never be used again.

I learned a lot that day about common fastener sizes and to always be nice to the machine shop head.

Oh yeah, the magical “chart”. As a tiny company / machinist shop I dread the day I have to order everything on it. But at the end of the day, it saves people hassle and you always have what you need. Luckily so far I only make stuff for my own use in the main job, which is injection molding.

It was only a particular kind of RJ45 boot that caused the issue, so if you are sensible and don’t use a cable boot you never ran into the issue.

i choose to believe this particular engineer saw the potential for this issue, but just hated those cables with a burning passion.

Just saying, this is not the fault of a single engineer but of a whole company that didn’t think “try all common cable types” should be a required testing step before a network switch goes into mass production.

Cisco is where good engineering goes to die.

You don’t have to test every cable boot. Just have a design guide that says “Don’t put buttons above or below ports.”

That can be difficult to accomplish…

Looks like they learnt and made a recess for the buttons.

And it’s not in the center of the port. It’s in between two ports where a boot should never be in the way.

That as well

if you are sensible and don’t use a cable boot you never ran into the issue.

Uh… huh? What, you’re anti-boot?

Boots suck. Good connectors just have the tab be more of an inverted V shape, so it doesn’t catch but you don’t need to squish a hard plastic boot to remove it.

Like in the image? That’s… a boot. Not a full one, but still a boot. (Side note: I’m starting to sound Canadian in my own head.) But I agree. The “snagless” ones are the best of both worlds: you can pull a cable through without it catching on anything, but still press down the plastic retention clip when the collar gets old and stiff.

Nah like this:

Instead of like this:

I’ve never seen one of those outside of this image.

They’re pretty common in nicer datacenter environments. Newer cat6a is only 28awg (tiny and easy to work with!) and can do 10gb just fine.

For example:

Ah. It’s better than nothing but I have still had trouble pulling cables like the top image. Those blocky edges get caught on things…

Yes.

I could see it also being a problem if you’re trying to remove a cable with a stuck latch. Wiggle it around a bit, accidentally hold down the button… oops

hey I have a photo of this saved too!

Why is it raised at all? This should be a pinhole button

Because that is just one use of the Mode button. Pressing it changes what the port LEDs indicate, so cycling it lets you see status, speed, duplex, PoE status, etc. without having to connect to it. That isn’t easy without a raised button. Clear could have been separated as a pinhole and that would have been fine, but this stupidly placed button would still have been useless this way anyway.