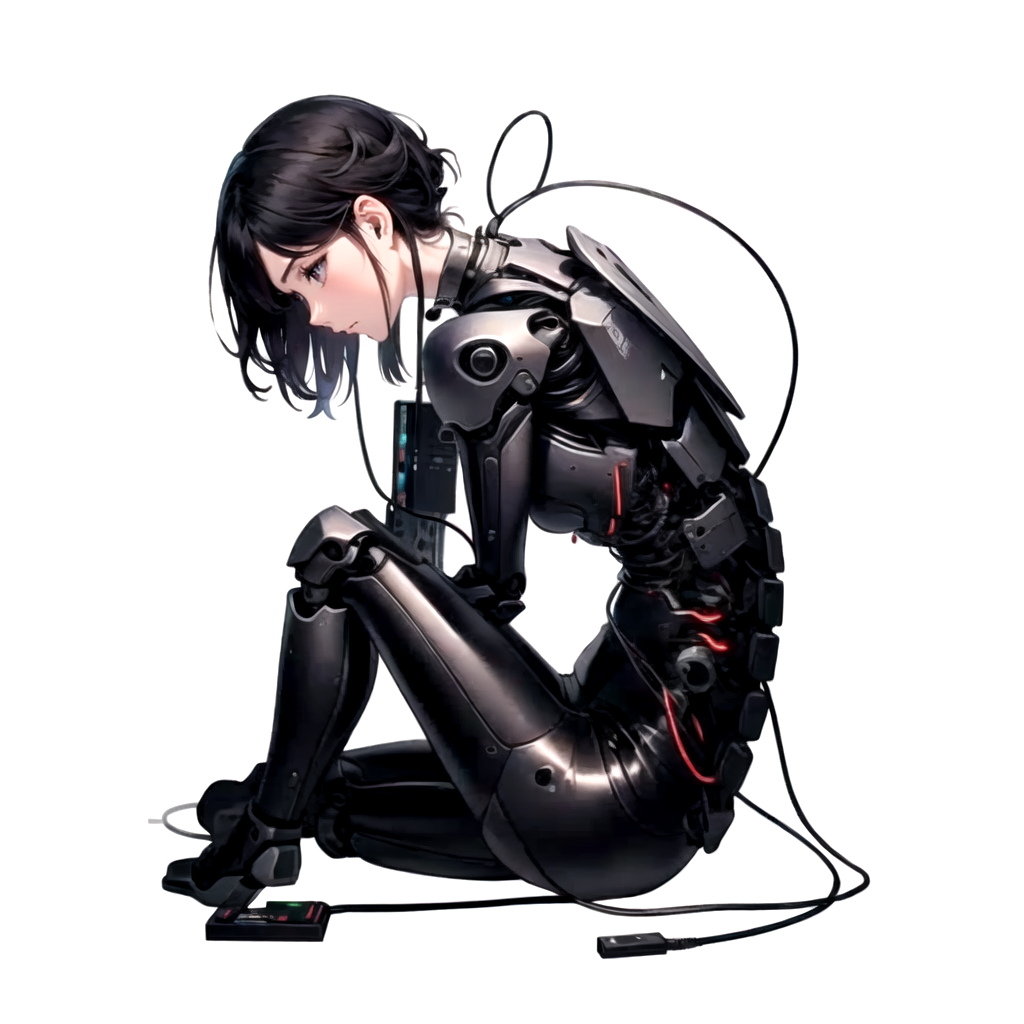

No idea what the deal is here.

This is on my slightly modded Creality Ender 3 Pro. (It’s got a CR-Touch, better springs, a metal extruder assembly, an upgraded official Ender 3 Pro motherboard with quieter stepper controller capability. Nothing all that invasive.) Identical gcode worked perfectly fine on my Ender 3 V2 Neo. (Which is sufficiently similar that gcode is interchangeable.) I’ve used that particular roll of filament for other prints before and had no issues. And the same printer has given me no other similar issues with other prints, including prints that were taller than where it failed on these photographed prints.

After the one on the right failed, I assumed it was a clog and did a cold pull. The second print (still on the bed) started out just fine, but started underextruding the same way at almost exactly the same place. I say “almost” because looking closely in person, it does look like the second started underextruding just maybe 3 to 4 layers later than the first.

I suppose it’s possible it was a second clog at almost exactly the same place on the second print, but it’s pretty coincidental if so. Plus recovering spontaneously on that second print is pretty weird.

I dunno. Just very weird and I’m hoping folks here have an idea what I might look into to find a solution. Thanks in advance!

Also, just a few more images in case it helps:

Update (finally): Thanks to all who commented. I printed it again with different filament and it printed fine. I’ll probably give the offending filament a dry, but I probably don’t have enough of it to try another print, so I may not get confirmation that was the (only) issue. Anyway, I’m happy it’s not some painful configuration thing, though. Thanks again for the input!

I suspect the retraction settings and or the extruder gear clamping on the filament to be the main issue. I upgraded my ender 3 pro to direct drive for a similar issue. Essentially what happens is that the extrusion goes smoothly when printing long uninterrupted sections, but these under extrusions would appear near or after areas that required a lot of retractions. If your retraction distance is set too small (5-10 mm) the filament gripping gears on the extruder end up going back and forth a lot on the same section of filament in order to start and stop quickly. This wears down the filament itself and suddenly the gears don’t have any traction on the filament to push it, and hence the under extrusion. This is fairly easy to diagnose however. You should check if there is a lot of filament dust around your extruder gears. That was the smoking gun in my instance. I fixed it by reducing the tension in the spring loaded arm and reducing the retraction speed while upping the retraction length to 15mm. I ran with those “fixes” for quite a while before upgrading to a direct drive. Hope this helps.

Either your slicer is failing: try shifting the object a little or rotating it and slicing it again.

Or your Z axis has something happening at that spot. Try cleaning and lubing it and see what happens when you jog through that spot a couple times.

I had a case that looked like that, because the nozzle was scraping the previous layer of the print.

I think that for some reason the layers below were physically taller than in softwas and the additive effect of that stacked and reached critical failure at a certain height. It started as soft scraping and got worse as it went on until it failed like that because it essentially skipped a whole layer. No enclosure/heating chamber btw. It was always the same height for that model, but then a smaller model like a benchie would have no issues on that height. I guess because the filament was warmer due to the smaller loops, so more mendible or less expanded somehow, idk.

I dried my filament so it stopped making bubbles and ran some filament specific calibration and also I changed the extrusion to be a bit lower. Then the issue was gone.

The fact it happened at the same z location twice is telling.

Try a slim vase-mode print that reaches past that height and see if it happens again.

Looks like a clogged nozzle to me. You can try a cold-pull procedure to clear it: https://help.prusa3d.com/article/cold-pull-mk3-s-mk2-5-s-mk3-5-s_2075 (maybe Creality has specific instructions for your printer)

It’s definitely being under extruded. As to what’s causing that, my first guess would have been a clogged nozzle… but if it’s happening not-at-random, it’s probably not that.

is there a way to see a log of hot end temps across the prior prints? it could be that something is causing the the machine to speed up putting out more plastic and the hot end struggling to keep up, though I’m just spitballing here.

Is your fillament dry? I have horrible prints like this and tried everything until I decided to dry the fillament, solved it.

It looks to me like those clips that come inward a bit are under-supported and it’s leading to poor adhesion of the whole layer. You may try again without the “ignore or remove minor overhangs” equivalent option ticked.

Another common gotcha is water absorption in the filament leading to previous code no longer working with the same spool.

Error persists on entire layer where a new retraction pattern is used, therefore it is very unlikely to be filament humidity or a gcode issue, but filament settings.

What is your retraction length and speed? Do a cold pull to rule out debris. Reduce your retraction until stringing occures, observe if the error repeats. Temperature could be playing a role, but if your layer adhesion is up to expectations, I wouldn’t change. Also observe your nozzle and make sure it’s taught, I’ve been surprised how fast some of my brass nozzles have worn out even with non-abrasives, and causes a similar symptom of randomhish failures, especially if loose.

PS: sometimes a couple cold pulls are needed and try to hit different temps when you pull. I’ve noticed since PETG doesnt stick to PLA, to use PLA as a cold pull you actually need it warm enough that the PETG bits will flake off the inside