Torx is only good if your screw is non rusting it rounds off too fast with almost any sign of rust.

Torx kinda requires it be made of a decent alloy, it was developed to handle situations where you really really need torque. Handling more force than anything else was the guiding principle of its design.

Hence you find it in places such as bicycle disc brake rotor mounts.

I just use Torx for everything indoors. Granted a box of a 100 50x4,5mm wood screws lasts me a few years if i don’t have any project to pursue. No need to skimp a few € on this.

Torx deck screws are pretty standard now too. They work well and are usually powder coated. Our 10 year old deck is still doing fine in humid summers and frozen winters.

it rounds off too fast

You’ve had significant issues with Torx screws rounding off? I think it’s designed be the least prone to that. My personal (very minor) issue with Torx screws is they provide too much grip and torque. They will break before they cam-out and I’ve snapped off screw heads and the bits themselves, even hand-tightening.

If there’s slightly-deeper-than-surface rust the lobes get brittle and tend to break off.

Dude I wish I didn’t have to grind my torx off when the head rusted and teeth all ground off

Agreed i strip so, so many philps and hex screws. Although the combination screw has saved my ass, when shit hits the fan and i striped philps. I get bertha THE BAG ASS FLATHEAD

had to dremel one of my laptop’s (stripped) philip head screws to use a flat head screwdriver on it

it worked, somehow

You sure it might not have been a posidrive instead of Philips?

Everybody needs one big ass flathead just to demo with. The superior wonderbar.

Disagree. Torx are the easiest to strip. Torx bits literally last 12 bolts or so.

Hex should be B teir. Pozi should be C, it’s very common in the UK for low torque applications. But it looks deceptively similar to Phillips.

Hex could even be A tier except…

- 10 million metric sizes

- 10 million imperial sizes

- heads get full of rust or dirt

- note that this makes it even harder to tell which damn size they are

- usually mild steel so they strip, especially when it turns out you’re using imperial in metric and vice versa

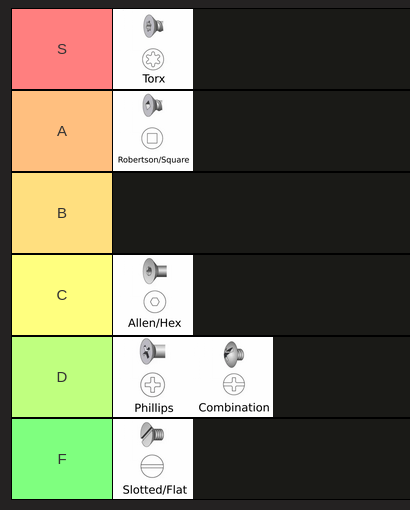

Too many years of wrenching on old equipment has soured me on all except for the good old fashioned hex bolt (S tier) and Robertson (A tier).

Even slotted beats most of these if the steel is decent, scrape out the rust and whack it with an impact screwdriver. I’ve turned many torx and hex in particular into slotted over the years.

There are not too many metric hex sizes.

There are too many imperial sizes, many of which have silly names.

Having cut the head off many rounded bolts I question your judgement.

what do you do?

External/male hex aka what big bolts have that you use a wrench for are A tier. I can’t really think of a more effective way to transfer large amounts of torque to a bolt or nut. Female hex aka Allens are low C or high D tier. They would rate higher, but they’re made in 8.23*10^19 sizes, and the correct one nearly never falls to hand. Add to that the tendency for allen wrenches to be made of low quality extruded hex stock and you’ve got an excellent recipe for an unpleasant fastening experience.

I rarely see imperial hex. Many Allan key set still come with imperial sizes but all contemporary products and screws come as metric now (in my experience in the UK).

Even with the metric there are still many sizes needed, which I agree is frustrating. However, it ensures the correct bit size is used for the correct screw. Unlike Phillips, pozidriv and slotted. It also limits the amount of torque that can be applied to a screw that is proportional to the screws thickness.

The prevalence of low quality screws and tools for hex drives is because they are cheaper to manufacture. Its unfair to reduce the rank of the drive mechanism for that. If the average hex screw and driver were built with the same quality of materials as the average torx this would be less of an issue.

I would recommend you use a screwdriver with hex bit heads instead of Allen keys, if you need to use hex screws a lot. Much more pleasant experience and much less likely to bend and twist like Allen wrenches.

Well designed things and screws should come with appropriate drives. I wouldn’t recommend using a wrench on internal hex drives. If they needed high torque they should be external hex like a traditional bolt. Only external hex, large torque and large internal hex should be applied with a wrench. Other drive systems should be used when hand tightening is all that is needed. I’ve learned the hard way tighter isn’t always better.

I appreciate your passion for the superior type of fastener. I work in both metric and imperial for all types of fastener and metric allen is the easiest to work with in my opinion.

I rarely see imperial hex.

(in my experience in the UK)

Well, yeah.

Yeah there’s no telling which standard you’ll encounter in the US, Probably both on the same machine.

And ain’t it funny that Allen is pretty much the only case where the most available drivers are cheap as shit L-shaped pieces of “tool” steel? Yeah, “allen screws and drivers are cheaper to manufacture” which is why they’re almost universally cheaper and shittier. Improve the quality of anything for the hell of it and guess the fuck what? The quality goes up. My algebra teacher taught me about that, it’s the transitive property of obvious bullshit.

I could be talked into bumping Hex up to B, I just want it between Phillips and Robertson.

I don’t have any experience with Pozi screws in the US, but doing a quick search they look like a solid upgrade over Phillips, so I’m guessing I would agree if I actually used them.

You get the self centering speed of Phillips with less cam out. It’s standard for most construction style work, very useful when you need to do 100+ screws a day.

It can be a bit of a nightmare when you first start doing DIY. Because you may not recognise the difference between Pozi and Phillips. Both drivers will turn each screw, but the wrong driver will make cam out and stripping more likely.

Pozidriv should be fucking banned oh my god why is it so common in the uk it’s so deeply inappropriate for 99.99% of applications

If you use the right driver and right size of driver. It’s very good. In my experience it’s much better than Phillips.

Torx, hex and Robertson are better, but they don’t self centre. So if your doing a lot of screwing, pozi drive is king. Because it self centres, it’s much faster. It’s great for construction type work (decking, plasterboard, walls etc).

If your doing more fine work, or need to apply a lot of torque it’s shouldn’t be used. But very long/thick screws tend to be external hex, torx or combinations of these at Screwfix/Toolstation.

Pozidriv is what Phillips should have been all along, except that bed has already been shat. It’s like the American electrical socket, someone made a decision in 1902 that we’re still stuck with and modern attempts to improve it just get in the way.

Pozi is amazing for household applications where you don’t need the torque of torx, and amazing for line work where screws won’t be touched ever again (framing etc.)

I feel like you didn’t give enough credit to slotted and combo (& hex but others have said that). Being able to be removed with a quarter or other coin is incredibly useful in applications where access to screwdrivers isn’t a given.

Yeah, combo is where it’s at in terms of field serviceability. I pretty much always have a flathead on hand, but very rarely have a torx but set, Allen key, or Robertson close at hand if I’m in the field.

I prefer flat over Philips imo, phillips very easy to strip

any screw is a flathead screw if you have a dremel

So couldn’t you turn a flathead into a phillips?

Not really. Philips requires to be pretty deep in the middle so that the sides have something to grab on to, which is difficult to do with a Dremel

I’m a technician and keep my 9 most-used screwdriver bits in its handle and all of these are usually fine for most applications… Except the slotted screw! I literally get annoyed every single time I have to use one, it always slips out and it’s significantly slower to screw/unscrew anything. Also, I only want to carry one, but if I use one wide enough to minimize slipping, it’s usually too thick to fit in the slot! “Screw” you, flathead screws and the $0.0001 you save with each one…

Here’s what I use most often (not necessarily in order):

- big Phillips

- small Phillips

- T25 Torx

- T20 Torx

- T15 Torx

- T10 Torx

- big security hex (hole in the middle)

- small security hex (hole in the middle)

- slot flathead

Hey now, you can’t just lump Robertson and “Square” as the same ones, one is assuredly better and it sure as shit as not square. Robertsons have a slight taper that prevent the bit from slipping out, and the stupid square ripoff has 0 angles. So if you use Robertson bits on a square screw, it gets super fucked, and if you swap it basically doesn’t work at all. If you use Robertson for both, its fucking magic.

TLDR: Square bits not same. Square bit bad. Robertson good.

flat beats Phillips you Philistine! sure it’s not self centering but at least you can torque it and it’s compatible with improvised tools.

Robertson Square that high up? This list must have a few loose screws.

I’ve used them very rarely, but I’ve never had one strip unlike everything beneath it so I can’t complain.

I can complain the screw bit gets stuck inside each time and due to it being barley used in the US they are a pain to find.

In Canada it’s my preferred screw. Sometimes it gets stuck but rarely, and if it does you just back off / reverse a little bit. Its amazing because you don’t need magnets to get it to stay on the end of your driver as you line it up so much easier to do everything one handed, rarely ever strips, and you can torque it a stupid amount if you want to

Example of a Canadian problem: Using impact driver drill to remove Robertson screws, the screws get stuck so good that you can shake the tool by the screw an it won’t let go.

With the exception of pocket screws, weirdly. Pocket screws are somehow all Robertson.

They’re used in cheap drywall screws and really suck in that application. The screw is too soft and the drivers are also usually too soft and strip. Once the driver starts to round over it’s ruined.

All Canadian carpentry is done with Robertson or nails, drywall with Phillips because you don’t want to apply a lot of torque so Phillips is perfect for that application because Phillips is shit.

That’s a shitty screw then not the style of head issue?

Those aren’t separable issues. A good drive system would do more to compensate for material deficiencies. A shitty torx screw is a lot better than a shitty robertson screw. Robertson is at best C tier.

I think torx are usually in higher end applications. So a shitty torx is going to be better quality materials than a equivalent shitty hex and Robertson.

I think you’ve been collecting shit square systems then. Try an actual set of Robertson screws with a Robertson driver, and you’ll have a very different experience. Squares have no taper, Robertson’s do. This is also assuming where ever you find them, they have named them correctly, but I swear they ain’t the same.

Because they aren’t the same, or compatible with eachother really. I use them a lot and can almost promise you the problem is when you involve the “square” one’s at all. Robertsons all have a taper, so you can kinda use square bits/screws either each other, but they will chew the shit out of each other. Squares will always slip/strip, Robertson is far better IME.

Allen/Hex is supposed to be C tier? Yeah right…

In theory they’re good, but I’ve had a few too many allen/hex screws strip and having both SAE and metric standards is irritating. Tool quality has been an issue as well, I’ve had shitty Torx screwdrivers last for years and years while a decent allen wrench will snap or wear out way faster. Still miles better than Phillips though.

Edit: also you can use Torx bits on hex screws, so more points for Torx.

Don’t use torx bits on hex screws. It is super easy to strip them that way, and even easier to get the bit stuck.

You are right, but it has also saved me a few times when hex bits/wrenches weren’t readily available.

Torx screws might last for years, but Torx bits don’t last for more than a minute. Bloody hate them!

Thwy strip, and good luck with torquing them to anything. I can’t count how many times I had to drill out hex screws, and I don’t even work with metal that much

I do like a good Robertson. Don’t even need a magnetic tip to hold them on.

I’ve literally never in my life seen a square or robertson screw. Pozi though is like 90% of all screws.

Very popular in Canada

Most electrical panels use Robertson from my experience

deleted by creator

I see Robertsons sometimes in the decking hardware section at home Depot. Or torx over there too a lot

Cabinetry screws also

I found a screw that was a tamper proof torx apparently. With a hole in the middle. Is that even higher up?

Ah, the worlds best security screw, the one you can open by jamming a flathead in it.

At a glance the Philips screw looks like a sad face. It’s like it knows how it makes us all feel

The second any dirt or rust get involved that scale gets inverted

Square is best here imo

Torx >

This is correct, Torx is easily the best standard. Robertson is an acceptable second.

Posidriv can bugger off too.

When you look at a Robertson, or a JIS or even a Phillips you just use a JIS or Robertson and you’re fine. If it is posidriv, you must use posidriv and you can’t use posidriv with a conventional Robertson/Phillips/JIS. The only way you can tell the difference is by a teeny-tiny little dot on the screwhead or some extra minuscule fins on the driver. If you do t have your glasses, or aren’t aware, you will damage the screw and your driver.

Hex and Torx are OK for certain things where you don’t want an ignorant pleb to gain access. Security Hex and Security Torx are OK where you don’t want an ignorant pleb in denial of their ignorance to gain access.

All those other drivers, Triwing, Pentalobe, variants of Posidriv are just there to push proprietary applications and should not be used by anyone.

Oh my god don’t get me started on pozidriv. Not only is it actually really spelled like that, it was literally fucking designed to limit the amount of torque applied to the screw. Fuck my life. Whoever decided to put that fucking hateful abomination on a 4 inch self tapping wood screw needs their fucking head examined and no mistake oh my god. Fuck.

it was literally fucking designed to limit the amount of torque applied to the screw.

Other way around - Phillips were designed to torque out. Pozidriv are much better for high torque applications

Phillips were designed to torque out

That’s a myth/misconception too. Phillips is not intentionally bad

Yeah, it’s just regular bad. And since its invention people have unfortunately turned this bug into a “feature”.

Are you saying you use a Phillips screwdriver on Robertson screws on you savage?

No one should ever have a Phillips screw driver, unless it is actually a JIS or Robertson.

Robertson is a square, you’re thinking about pozidrive

If it is posidriv, you must use posidriv and you can’t use posidriv with a conventional Robertson/Phillips/JIS.

Uh…you can use pozidriv or Robertson tools on pozidriv fasteners without issue… I think it’s the only standard that has cross-compatibility with another standard like that.

Robertson is top tier too

As someone who owned a Jeep in a place where they salt the roads in the winter. Fuck torx.

That being said no other screw head would have been any better, and maybe it was just a cheap torx socket (you could see I had actually twisted the whole head on the tool, before stripping the screw). A hex bolt for that particular application would have been much easier to remove (or snap the head off :p)

Applications exposed to corosion really should use external drive fasteners.

I wonder if there are fasteners and sockets that have both. I imagine hex + torx would handle a lot of torque

I don’t like that I need a particular size bit. With Phillips, I can grab most screw drivers and they’ll fit most screws.

So you’re the one stripping all the screws then!

I find Torx unpleasant to work with.

Me out here calling them “plus head” and “minus head” like a neanderthal

we call philips “cross” and flathead “slit”

‘cross-head’ and ‘flat-head’ for me

We call them “star screws” where I’m from

I have been around tools for a long time. When someone asks me for a screwdriver I always ask, “Plus or minus?” to see their reaction.

“Times.”

Neanderthals were on to something then

omg I’ve found my people, you all have strong opinions on screw driver geometry

Might I recommend a book on the matter.

One Good Turn: A Natural History of the Screwdriver and the Screw by Witold Rybczynski

Hey cool my grandfather was named witold. Probably had some strong opinions on screwdrivers too tbh.

Cheers for the recommend

Torx and Robertson are the best.

Linux and bit heads, Lemmy is definitely my place lol

Slot screw drive gang rise up!

No.

It pries, it scrapes, it can do anything!

I always know I’ve found my people when they have extremely strong beliefs on everyday household items. My favorite was a 3 week argument about electrical sockets on Reddit a few years ago

I fucking hate Phillips style so much.

Never tried JIS though, Robertson is where it’s at.

Do you have a moment to talk about our Lord and Savior Torxus Christ?

Torx is the one true god

And his disciples are Pozidrive

Who TF still uses Phili… Oh, it’s you lot again 🤣

The knock off Robertson? Why would I use that

What is the reason to use torx over Internal hex (Allen key)? Surely there must be a reason why it’s used

When growing up it used to be that (internal) hex was for high strength but needed exact tool size, and Phillips/flat blade for low strength application with the benefit of any approximately sized tool will work.

Seems to me torx is in this awkward in-between where it’s used for low-strength applications, but require exact tool size. Or it’s used interchangeably with hex, requiring two sets of tools available at the work site (not fun if the work site is 30 meters up some ladders)

You can get more torque on a torx than an Allen. They’re basically the same shape, but torx has longer contacts on the star points where the hex corners would be.

Also, M1.5 hex is getting a little too close to a circle, and you can forget about going much smaller. M1.5 torx is still usable.

Also (for the same reasons) Torx heads don’t have to be as deep for the same torque as an Allen. More space efficient.

Torx is a lot less likely to strip out the tool or the fastener than Allen, especially at smaller sizes. Torx comes in a smaller variety of sizes than Allen does, so it’s more difficult to choose a slightly wrong size. Especially with Allen being offered in both metric and moon landing fractionals, there’s like, M0.8, and 14/93", one of which fits slightly loosely in the other and will sorta work, until you turn real hard on a stubborn bolt and round out the screw and/or driver.

In other words, it is my experience that you’ll have a large pile of allens that you can’t realistically tell apart, and a set of like 8 Torx tips from which you only use like three.

I see. It makes sense when you say it.

Yet I only encounter torx on low-medium torque stuff. Applicances, not cars.

Jeep doors are T50

Found the Canadian

But not #1, or most of #2, in common stainless alloys. Even dry film lubed and drill tip is insufficient to prevent the torque from exceeding the (relatively low) yield strength, leading to stripped screws from standard driving in any wood denser than about G=0.45. There’s simply not enough contact area to prevent it.

Stainless fasteners are niche and require stainless tools, full-stop.

Most fasteners are not stainless.

require stainless tools

You really don’t want to use stainless tools as they will plastically deform. Roberson is just not that great for torque-transfer geometry; it’s advantages lie elsewhere.

You really don’t want to use stainless tools as they will plastically deform

They are made specifically for stainless fasteners.

You’ll frequently find them in the toolbags of aerospace professionals and industrial electricians and they are really the only folks that deal with a lot of stainless fasteners.

Bicycle and motorbike folks have lots of stainless hardware, too. And lots of time you’ll see folks blame JIS/Phillips on ruining their fasteners, but sometimes it’s just because they’re using toolsteel tools on stainless fasteners.

90% of complaints about any screw head type is some jackass using the wrong driver like a P2 in a P3 head totally mystified as to why their shit stripped.

That’s not just user error, though. Phillips also makes it easy to use an undersized driver, and people will grab whatever they have handy. Torx doesn’t have that problem, but at the expense of needing a bunch of different drivers for different screws.

Yeah, I’ll take that trade off pls

You’re suppose to have a bunch of drivers for Phillips. When you don’t, they strip. It’s not a real tradeoff.

I mean, yeah, exactly. And right now I’ve got fucking loads of both and more so give me types that won’t strip pretty please

Nah, it’s user error. Torx also has the problem. I’ve had to rescue multiple laptops from one of the IT guys at my work because he keeps using a Torx bit a couple sizes too small and stripping the heads.

Well, don’t forget that a philips head screw was designed to slip. It was designed as a poor man’s torque-controlled screw. This is really part of the problem. If you use hardened steel drivers and screws this is not a problem but often it’s pretty low quality and the slipping will cause damage to the head and driver.

I prefer torx for this reason. But most of the screws I use I don’t pick, because I do a lot of repair work.

Phillips was not designed to cam out. It cams out so people started saying it was designed to cam out.

Phillips was designed to reduce cam out, which it does, compared to slotted.

Yep, it reduces cam-out. Not very well, but it does better than a slotted screw made by a drunk apprentice with a dremel being torqued with a flat-head prybar. Torx, Allen, and Robertson all reduce cam-out far more, but Phillips still sadly get used in new products.

Phillips was designed to be simple to cut and self-centering, so it could be used on assembly lines. It exploded in popularity just as mass manufactured goods were becoming popular purchases.

Later styles like square, Hex (cut) fasteners, or 12-point (both types) or Torx can create higher torque without slipping but are not centering the way Phillips is.

Common misconception.

How do I identify the screw head size by sight

Same way you identify which wrench to use on a hex bolt: You get a feel for it over time and you find the one that “fits” right.

You should be able to lightly rest the Philips driver in the head of the screw, and the tip should touch bottom. If it doesn’t touch the bottom, go a size smaller. If you can rotate the driver in the screw head, go a size bigger.

When in doubt, it’s probably a #2.

You know that is so obvious, but it makes me realise how unintentional I’ve been with my screws. I will do better.

That’s a major flaw with Phillips drive though; it isn’t that obvious. A #1 and and #3 driver will pretty much turn a #2 screw, unless the screw misbehaves and needs a little more torque to tighten or loosen, then you’re that much more likely to cam out and damage the screw, the driver or both. But Philips screws do that anyway even with the correct driver size, so.

It’s fucking stupid though. Just use like three. Not 25

Pozidriv enters the chat

How does a positraction on a Plymouth work? It just does.

Isn’t Positraction a GM trademark?

I wonder how many pozidriv screws have been stripped and a Phillips driver has gotten the blame.

I’m trying to understand what the top half of each diagram is

The tip of a screwdriver

Why does it look like a clam shell

You’re seeing the cutouts that bite the screw, and you’re reading them as being 3d arcs that extend back. Instead, follow the two vertical lines representing the main shafts downward, and look at the whitespace between the shells as the bits of the cross that poke out, and the “shells” as the grooves in the shaft forming the cross.

Oh my god thank you haha

Thanks I needed this.

Taco

Aww Jis

Mother. Fuckin. Superior. Standards.

All that lame stuff. Torx it is.

Phillips is just common in consumer goods as it’s designed to cam out when over torqued by the average joe. Better to have it stripped but tight than a broken head.

Still sucks balls when you know what you are doing though.

It’s not designed to cam out. It was supposed to be a quicker alternative to slotted. It cammed out a lot, people then claimed it was a feature.

Looked into it a bit and you are right, it wasn’t intended. The articles I’ve read all mention camming out as an unexpected bonus.

It’s not a bonus. It was explicitly designed to reduce cam out. It is a flaw.

Torque limits can be managed with the type of diver used. Screw drivers are limited by human hand motion, wrenches by length and electric drivers by power/clutch/gearing.

If you wanted limited torque application you change the method of driving, not the drive head. Mr Philip would understand this and everyone he sold it to would as well.

There are few use cases where you would want to limit torque by camming out and potentially damaging the screw, component or operator. Stripped screws are a nightmare for everyone involved.

Screw you

Pozidriv > *

Not only is it self-centering like phillips and JIS (eg the reason they are used in so many line-assembled manufactured goods) but it’s has superior contact like a Robertson (square drive) or hex or torx.

Torx > *

Torx’s highest-in-class leverage without camming out gives it superiority in some applications (eg impact-rated deck screws), but if you had to choose one fastener head for everything, posidriv is it.

Torx is not self-centering, and therefore inappropriate for many tasks including anything not hand-assembled. It is also susceptible to stripping out after rusting.

Isn’t it proprietary?

The patent is expired and it now has ANSI and ISO standards.

That guy loves jis lol

It’s not about the depth, it’s all about the angle.

Sounds like someone is working with a small screwdriver, if you ask me.

Fuck your limit screws

-Shimano, probably

Wait…shit. All those arguments I had with my Ninja suddenly make perfect sense, the screws on the goddamn carbs were JIS and not phillips. fuq.

Yep, very important to know for Japanese motorcycles, they all use JIS.

Higher-end bike parts might be the one application a home DIYer might encounter stainless steel hardware.

Stainless hardware is generally pretty uncommon, but most common in things like commercial kitchen equipment, aerospace and industrial machine panels.

In those industries, the pros know and carry specific stainless steel tools, because using normal tool-steel tools will destroy the hardware.

tl;dr Phillips, pozi or JIS, you might just end up shredding the softer stainless bicycle hardware with your harder tools.

Aircraft repairman speaking: I’m not worried about stripping out stainless screws. If anything Stainless steel is tougher than a cad-plated standard steel bolt.

Aluminum fasteners are the ones you’ve got to treat like a sore pube.