My dad was a boomer, he insisted that Phillips heads didn’t used to strip out this bad and it’s just that everyone switched to making shit cheap screws out of shit cheap material. He also lived to see the enshittification of appliances from something you buy once in your life to something you buy every five years (at least, according to the warranty) with a nifty galifty payment plan. Walking into home Depot instantly radicalized him.

I think I’m with your boomer dad on that, though. Screws are increasingly cheaper and shoddier than they use to be, and probably because of the materials used are light and easy to produce. Now, the boomers blame “them dang cheap Chinese screws” but we all know it’s enshittification for the sake of profit (which I guess can and would include globalization of supply chains).

True, but on the other hand, the drills or impact drivers are also getting stronger and stronger, so it’s easier to mess up a screw. And then there’s the driver bits, they’re so bad these days that every new box of screws comes with a free bit.

I still hand screw things and they still break even with the right size driver, haha. But yes, those titanium coated bits make quick work of aluminum screws.

Your dad is right. I never used to strip out Robertson deck screws. Now, if you’re lucky enough to get a screw in, the chances of getting it out unstripped approaches nil. If I search around and find good brands like Richileu, I don’t have that problem. The shit Chinesium screws at Home Depot today are horrendous.

deleted by creator

He forgot to mention that after Home Depot, he stopped by Timmies on the way to his rec hockey game

And their vehicle runs on maple syrup

i’d believe it to be honest, problem is phillips is still shit. You put ANY torque into them, you’re gonna need to put a LOT of back pressure on them. Which is the primary reason they tend to strip anyway, inadequate back pressure, causing the bit to slip, getting a purchase on the fragile little corners, and then fucking DELETING them from existence.

I am old enough to remember when they only had manual screw drivers and thicker wood screws that needed to be pre-drilled and lubed with soap.

Go buy a modern “cheap” wood screw. Not a deck screw. An actual wood screw. Pre-drill the correct size hole, including the countersink, and use the correct size manual Phillips screwdriver. You will never strip out the screws.

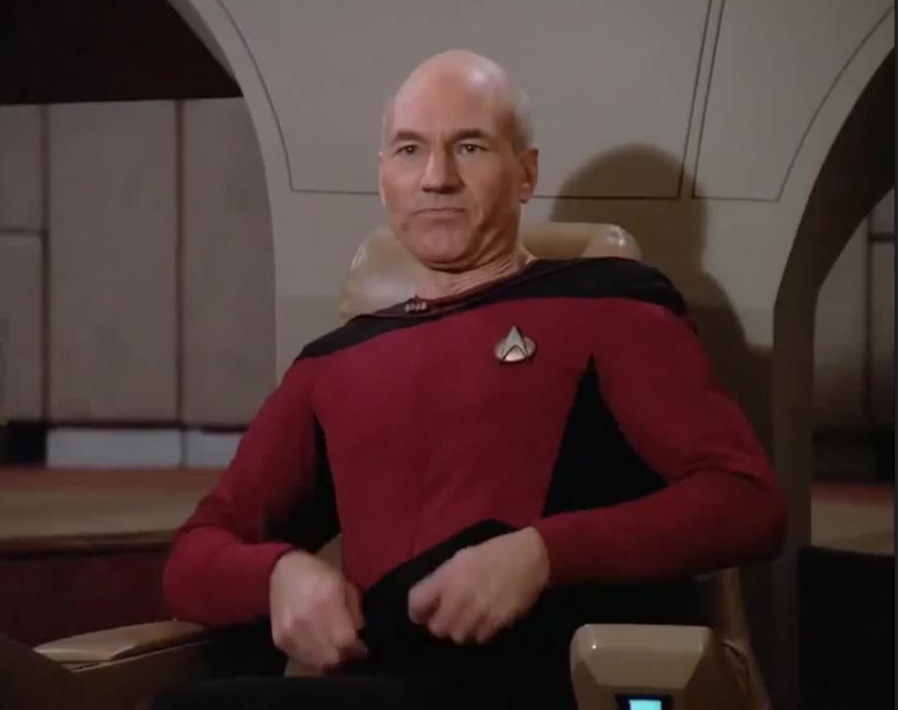

Now take a 500 RPM impact driver that has almost enough torque to remove lug nuts, a worn or wrong size bit, and a thin shank screw that was only designed to hold down deck boards and the slightest slip or misalignment and have this photo.

We all do it because it is fast/easy. Just understand that you are doing things the convenient way instead of the right way, and you have to expect the stuff to sometimes not work aa advertised because of it.

I’m a millennial, I don’t really recall phillips screws getting universally worse over my lifetime. I’ve torn the drive out of a LOT of them over the last three decades.

What I have seen is Phillips holding still while the rest of screwology improves around them. Take an impact driver and blast in a few 3.5" #10 Torx deck screws, then try to install a Phillips head screw and see if you can keep the word “bullshit” from coming out of your mouth.

There’s also the issues of Pozidriv and JIS, which both superficially resemble Phillips but are different and work VERY poorly if turned with a Phillips driver.

Home appliance enshittification is real though. I’m running my Kenmore 80 series for as long as I can.

Millennial here, too. Phillips screws have been made of fucking cobwebs and wet tissue as far as I remember too.

Gen Z who fucks with old tech here. Some eras had pretty good philips but im not convinced the head wasnt reinforced compared to the rest of the screw. Id say tech on average philips get worse from about the lste 70s onward, for cars its the mid 90s.

deleted by creator

Torx gang reporting in 👌👍

Snap the bolt before you ever strip the screw. I hate regular alan keys, torx should be the default everywhere. I did lose too many torx bits when impacting though

deleted by creator

I have no idea how you managed to overtorque a torx honestly. Especially since you say alan key doesn’t do that. Alan keys are okay-ish when used on M5 and more. But stripping smaller screws than that is so common it’s almost useless. Also good alan keys have a small ball bearing on them on the ball side which lets you hold the screw on it or “free spin” as you call it.

deleted by creator

Try a Wera, that’s what I run now. Expensive but worth it. Got both alan, alan imperial and torx.

Fuck that Alan guy

One of the IT guys at my work is really good at stripping torx, but that’s because he uses a driver a couple sizes too small.

That’s just… Wow.

the sizes are definetley hard to figure out, but the “if it wiggles, it’s too small” rule applies to torx as well.

It’s nice that they have a special skill 💜

He needs to get himself an I fixit kit.

After he did it the first time, I linked him a nice Wiha set. He stripped more a week later because he hadn’t gotten around to buying the screwdrivers. (iFixit is great too)

Why doesn’t he just use some kind of drill bit to ream out the hole? Seems easier and gets there quicker.

torx

That’s a brand name! Just call it hexalobular internal

Torx is a trademark for a type of screw drive characterized by a 6-point star-shaped pattern, developed in 1967 by Camcar Textron. A popular generic name for the drive is star, as in star screwdriver or star bits. The official generic name, standardized by the International Organization for Standardization as ISO 10664, is hexalobular internal. This is sometimes abbreviated in databases and catalogs as 6lobe (starting with the numeral 6, not the capital letter G). Torx Plus, Torx Paralobe and Torx ttap are improved head profiles.

6alobular brah 🤙

Torx bolts in the T40+ size that are exposed to moisture are impossible to remove. I’ve just moved to welding a nut on before I even go through the trial of breaking off half a dozen bits and then doing the same.

+1 for torx. Have actually snapped screw shafts with those

The poor man’s Robertson

Go back to Canada!

Who needs more than 4 sides anyway?

That’s the whole difference between torx vs Phillips.

Theoretically, you should never break a screw shaft with Phillips because they are designed to cam out before enough torque is applied to break the shaft of the screw.

It’s supposed to be a feature

Still gonna use torx because once a philips cams out the screw as well ss the tool tip is useless

I believe this is actually a myth, post-hoc reasoning to explain away a shitty design

honestly torx is still garbage. the tiny ones on the bottom of tech products that get cemented in still strip like nobody’s business.

Tech products often use stainless steel bolts, which are a lot softer than a normal steel

alrighty so torx screws are just shit in most cases you encounter them

I’d say by sheer count the majority of Torx screws I’ve encountered have been for deck boards, not tiny tech screws. And they were excellent.

phillips doesn’t scale any better. i’m actually glad whenever i see torx on small devices instead.

Never have for me. I dont turn til fully seated

I ain’t screwing with half my ass off my seat

Your choice, kudasai ;)

Idk man, I’ve been working IT for 10 years and have never stripped a torx. Didn’t know it was possible

Oh, the heads not quite flush, lemme give it juuuuuuust a bit moreahhhhfuck

Maybe if I just stop, align it perfectly, put more pressure behind it and gently start tuuuAHHHFUCKOFF!!!

Life pro tip: If you ever need to remove the beautiful piece of art shown in the post, Dremel with a metal cutting blade to create a flathead screw, then remove it.

I’ve done that. It often works, but you have to be careful not to go too deep, or you’ll just break the compromised screwhead right in two once you start with the flathead.

That’s a fair point, only just enough to get the job done. Otherwise you’ll have to either tap it out or get really creative with JB Weld and half of another screw.

Snap! Can’t even put a new one in…

+1 for torx being available in america. +1 for robertson existing at all.

pozidriv is pretty cool, but annoying to use since people confuse it with phillips all the time so you end up with a lot of stripped screws.

torx is the way to go. their sizing is odd, but it transfers torque well and is wear-resistant.

Robertson obviously.

The only one I’ve never stripped out. I’ve broken drivers before I broke the screw!

Coming in clutch

Double hex and triple square just have to be just as bad as all the Phillips variants. I can’t see that being a reliable shape for a screw

My GTI had triple-square bolts for the seats. The bolts were maybe 1/2" diameter, and I was able to comfortably get a lot of torque on them. Weird design though, and can’t imagine it holding up on smaller, softer screws

“It’s a Pozidrive bro, you can’t- you can’t just use a… annnnd you stripped it”

Partially stripped phillips? Grab a flathead screwdriver close to the same size and use a hammer to tap it down into the screw head. Twist it out while pushing down.

I turn screws as part of my job and can’t eait to try this

Get yourself some real screws get yourself roberston

Canadian invented square Robertson screws are the best.

- they hold on the tip of the screwdriver at any angle

- the hole in the screw head doesn’t get all messed up because you can’t fuck it up.

I wish that were the case, but most store brands have enshittified to be made out of cottage cheese. Even robertsons have this issue now if you don’t search around for good brands. Generic trash is trash.

I’m in the process of rebuilding a house and a new shop, and the last time I did this, it was nowhere near as big of a problem.

I’m a screw stripper

How do I tag a comment nsfw

If it’s wrong to be turned on by the sound of a DeWalt cordless drill, then I don’t wanna be right.

At least it’s not a a Kobalt.

your mistake is using philips

Yeah, Torx is the way to go!

torx 4 life

Nah, Robertson

Thing is, I wouldn’t even know where to get those. Torx is readily available, often even at an Aldi.

They’re everywhere in Canada. Just depends where you live tbh.

Not always a choice we get to make, but I see your point

Here’s a tip for anyone with this problem. Take an elastic band and place it over the devastated screw and try again.

I’ve tried this hundreds of times and it’s never worked.

Of course not. But it’s funny to watch you try.

I posted it above, but the best way is to Dremel with a metal cutting blade to convert it to a flat head.

Source: I used to work for Home Depot and had to fix shit for people all the time.

I was very confused until I realized you mean flat elastic bands which I’m not so familiar with (the ones I’m used to, have square cross sections).

Latex gloves also work alright in a pinch

Neither of those really work when the screw is hard to remove, and quite often those which you strip are hard to remove. If you put the same damaged fastener back on and then can’t remove it, that’s on you though.

Yeah definitely never put a stripped screw back in. Replace it or just leave it empty

Just like my lug nuts.

Amazing how far you can go with just two.

Fuck Philips. Pozidriv is so much better.

until someone tries to use a phillips bit on a pozidriv screw.

pozidriv is better, but at that point, just use torx.

I think both torx and pozidriv have their place. Torx for any screw that needs a lot of torque, is in a hard to reach place or for really small screws.

When I have lot of screws in a simple application, like driving them directly into wood, I prefer pozidriv though. Due to the conical profile, the bit just automatically slides in correctly. Also, torx just has way too many different sizes.

fully agree, both have flaws and advantages. but both are better than phillips.

skill issue

Half my laptop’s screws are like that and it drives me insane trying to open it now.

Laptop screws are usually JIS instead of Philips. Get a JIS screwdriver and you won’t have that issue in the future.

Or just stop screwing your laptop and go jis somewhere else

I’m impressed you managed to thread that joke in here.

It was right there in the groove, you just had to send it.

Ugh, I clearly don’t fit here. Going to go for a drive.

Come in, it’s pretty simple… machine. Fuck.

I don’t think there’s enough screw puns to keep going, we’ll have to start rotating some of them back